|

|

A pair of ultra lite radiators to keep Dan Leaches Rotax engine cool &

full of water. We recored these as one of the originals developed a leak

& both had stains in the tubes - mixed inhibitors. Not the machine to

chance a water leak with either! |

|

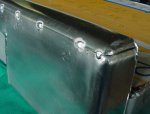

A bike radiator we recored for a customer.

Note our weld of the tank/header plate seam. You will not see this out

of most workshops. If you are quoted a price, it may pay to ask to have

a look at a comparable job they've done, as it's easy to weld 2.5mm

alloy, but it's not when it comes to 1,0mm alloy. |

|

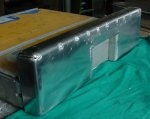

Ross Gault asked us to make this radiator

up for his '73 Camaro. Although it's powered by an 11:1 avgas burning

383 cube small block & going to do street/strip service, we only used a

37mm thick core as it has a large surface area & 14" fans don't pull air

through a 57mm core as well as a 37mm core. Stop/start is the only

driving in question, so the thinner core has an even chance of doing the

job bettter. |

|

We made this radiator up for Ivan Vellas GQ

Patrol which sees some real rugged use in competition. No point in fancy

polishing here! No bloody point in a 57mm dimple wall tube radiator

either as he said it made very little difference to the cooling -- both

high speed & low speed. Our second problem job in 3 1/2 years. We had

the core made in 10fpi for us, so air flow through the core should not

be the problem. I have one modification I want to try, but both of us

have been too busy to hook up with a time yet. |

|

Troy Taylor Races a real nice '28 Roadster

in Super Gas with Chev. small block power. We made this radiator up for

the car with matching breather tanks. There is a pipe on the back of the

AN fittings which bends down & there is baffling/filtration inside as

well. We also fitted an auto .trans. cooler in the bottom tank as the

alloy radiator has a big safety margin in it's cooling efficiency,

meaning the extra heat will not raise the water temp., but will

definitely stabilize the oil temp. for more consistent shifting through

the day/night. |

|

Keith Fracknell @ the Cobra Shop (Kippa

Ring) had a customers kit car that was running too hot, so we built him

this unit. Notice the top of both tanks are angled down. This is because

the core was made higher than the one normally fitted, so it allowed the

radiator to fit under the slope of the nose cone. Hardley costs anymore,

but gives extra cooling. Small breather pipe in top of the inlet tank,

is too make sure the radiator is always completely full of water, with

no air pockets. If you get an air pocket in your engine, it can really

do some damage by the time it works it's way back into the radiator, as

it turns too steam, which is a higher temperature & causes a localized

hot spot, which can cause a cracked head or blown head gasket. It can

also cause corrosion in an alloy head. |

|

Ron Johnstone drives one very loaded 1990

L98 Corvette coupe. John Bondock pieced together a stout engine for Ron

using Lingfellow heads & injection out of the States. With this 57mm

dimple wall tube radiator, the water temp spends most of it's time on

the thermostat. I've heard some people say that is too efficient & hard

on the thermostat, garbage, I'd rather replace a thermostat every 4

years & have my engine running very close to the optimum temperature for

ALL it's life, than have an engine that gains 6deg. every summer &

another 8 deg. every time it gets worked hard. These people are either

too tight or ignorant to the increased wear/decreased performance, a hot

engine causes. Remember, you can also run an engine too cold, but that's

what thermostats are for. |

|

|

|

Mick McGreggors Datsun 1600 SR20 DET Radiator

Part of

Modular unit with intercooler and header tank.

NB. The two pipes on the right

side are small top bleeder hose and bottom is the larger fill pipe. No

cap was used on the radiator. we use stainless Allen key button head

bolts whenever possible- neat! 37mm 2 row core.

Showing top mounts

for Davies Craig fan at rear & onto body at front. |

|

|

Mathew Paton. Chev / HQ

Holden

Mathew wants to look after

his new engine, so we made this up for him. Core is 45mm taller, which means

not only more cooling again, but makes full use of a 16" Davies Crag fan.

Remember, this fan pulls ( just ) more air than two 14" fans! The

mounts on the tank mean there is nothing sticking through the core to hold

the fan, & so will never cause a leak. The top tank is 15mm shorter than oe,

to help offset the taller core. |

|

|

|

Scott Sharp. Stroker 308 / HQ.

A direct oe

replacement radiator in 2 row, 57mm thick aluminium. Nothing fancy, just a

smick, super efficient unit. |

|

|

|

Geoff Nothdurft. 36 Ford / Blown small block.

What a tight fit this was. We

wanted to give maximum cooling, but there was little room with the blower

drive, so the fans had to be on the front. Not ideal for high performance

cooling. A 57mm thick core with two rows of the new dimple fin tube

means he has plenty of heat dissipation, & one 16'' & one 14'' fan make sure

there's plenty of air blown through to take the heat away.

The two "ears" on the

top tank are for the mounting rods that go back & secure to the firewall.

Not scientific, but

Goeff said if the top tank was 10, it was very hot to touch, core at

the middle of the 12" fan was 9, core at the middle of the 16' fan was

3, & the bottom tank was only warm to the touch! That's the type

of effeciency our radiators give.

Note that both top &

bottom tanks have allot of rear overhang on the core. This allows the blower

drive room (they cover 1/3 of the belt) and maximize the cooling surface

area for the given height. The bottom tank also holds the necessary larger

volume of water than the top tank. The top tank is shaped to both take up

minimal room and dispurse the water evenly into the tubes, which

is of paramount importance in an application like this height / width ratio.

The tubes are very long for the number of them, so it is important to fill

each tube as equally as possible.

Close up of the pride

we take in the quality & appearance of our craftmanship! A radiator

like this takes many extra hours of time compared the average aluminium job!

( if you get what I really mean)!! |

|

|

|

|

|

Jason May. Nissan 300ZX DETT

Cooked the

engine at a Lakeside practise day. Good excuse for a rebuild & a

couple of big turbo's, so he ordered an upgraded radiator to protect the new

investment. 57mm 2 rows of new dimple tubes will do that. We

fabricated the radiator as a dual flow to eliminate the silly oe. cross over

bottom pipe, placing both inlet & outlet on the same side. It is

more effecient as the water travels twice the distance through the tubes, &

because of the thickness of the core, at much the same flow rate. |

|

|

|

|

Troy Quelch's tough 6cyl LJ Torana radiator.

Once again no cap is used on

the radiator. It is on the second part of this modular unit (a header

tank). Single rib lightly rolled into top of tank for a little

strength increase and to break the plainness.

Shows breather on top

of tank, across to the header bottle |

|

|

|

John Cantrill's 56 Chev,

502 GM Crate engine - some mumbo here!!

Was running big 3row 52mm

copper/brass WB Statesman radiator. We made this direct

replacement in 57mm high capacity internal oil cooler (both heats oil

quicker & then keeps cooler - a very good idea for streeters - as long as

radiator has high cooling capacity). Also wanted plain polished tanks

& side bands. Longer manifolds lined hoses better.

Close up of 10mm mount pin.

Our Miller welder is set up very differently from this weld, compared to

weld to a tank seam weld. |

|

|

|

Chris W icks coudn't keep his Holden 308 Toyota HZ75 Landcruiser

cool on the freeway if ever he HAD'VE tried to drive anything over 110 KPH.

We built this Radiator

& shroud for him. Didn't make it much better. We now have the shroud as an

osnament at work as we made it too close to the core! There is little room

between the electric fan & the water pump pulley in this conversion,so we

didn't have any room to spare. Unforunately, the core had too large a

surface area for the 16" fan hole,& "dammed" the air in at hih speed.Cutting

4 large holes in the corners of the shroud was the other alternative

It is a taaallll core giving

allot of surface area. The truck has a narrow front panel, dictating the

size core that can fit.

As can be

seen in this pic, even with the radiator as low as it will go in the

chassis, it still sits up the maximum it can above the radiator support

panel. |

|

|

|

Peter Mezaras's Blown Ford 351 stroker T Bucket Radiator.

These pictures are of the first Hot Rod radiator we built - see horrors

for the sad story.

All cormers are rolled,

whether folded or joined.

Tack welded & having a

trail fit to the core.

Note the overhange to

the rear of the bottom tank. This give a lower profile to the radiator

whilst supplying a reserve of water for the water pump.

The spring hanger cut

out allows the radiator to sit 30mm lower on the chassis, still gives enough

clearance for the water to exit the tubes above, & gives a channel for a

full flow of water to gat across to the outlet pipe.

Close up of the cut

out.

Note the internal

double welding of all joins inside the tank. The customer doesn't know

they're there, but we do.

We wanted to mount the

radiator with rubber insulators, but couldn't come up with a 100% way of

locating the top of the radiator on to the engine without spoilling the

"look", so finisshed up solidly mounting it.

Double 4mm plate was

used for the mount & had to be welded together. Neat weld!

Waiting for the cowl &

a test drive. No, we don't test drive any customers cars, safer that

way. |

|

|

|

Craig Strong's Cobra Kit Car

Wants some extra cooling for

the West Australian Summer's. Big radiator needed strong mounts as

they had to be positioned on outer edge. Bottom gusset spreads load

over large area of tank. |

|

|

|

Steeve Moore's Datsun 1600 S14 SR20 DET (variable cam timing)

Radiator.

These two pictures show

the two plane taper we had to fabricate into the tanks too maximise his

cooling capacity. Maximum size core & minimum size tanks.

Also note the smooth

high build double weld on the inside joins in the tank.

The side taper allows a

full width of core to fit inside the header plates of the intercooler.

We are abit paranoid after finding Mick McGregor's radiator only just does

the job during severe service. We want all of our products to have as big a

over-performance margin as possible. As a result, the surface area has

increased (although we have to run the new Davies Craig Electric Water Pump

to make enough room), the core thickness has increased from 37mm to 57mm. &

in the new "dimple" tube, so we'll see how this goes.

The view the water sees.

The highly polished

exterior gives off reflections making the actual tank shape hard to

distinguish.

This is the finished

article. Horizontal tube is to slip the Davies Craig probe for the

electronic fan controller we sell, so if the radiator ever has to come out,

he doesn't have to worry about having to try & seal that bloody capillary

tube of old.

We mounted the Davies

Craig EWP directly onto the bottom tank, eliminating 2 hose joints, much

neater. Once again, fabricated mounts for the fan. |

|

|

|

This was our first recore we did back in '98. A Kawasaki 900

bike recore. The bike had been put down pretty heavily (read crashed) & was

too far gone too repair.

Pic. of the other side. |

|

Kris Kominski in Adelaide has a

13B rotary to cool. Bugger all room for the radiator, so we built him

this unit. Maximum core & minimum tanks! This is the smallest ratio of

tank depth we've used so far. the core had to be this wide to

accommodate the fan , which left very little for the tanks, so we

stepped the header plate back for both tanks which gives us wider tanks

for a larger volume of water. The right side return tank is only to feed

water evenly into the bottom half of the core, as the water whilst in

the tank, has negligible cooling effect. This is as thin as I hope we

ever have to go! Sure makes those -16 fittings look big. The core

is 57mm thick. |

|

This is my favourite radiator

of all the units we've fabricated so far. It is a real trick looking

little oe. replacement radiator, that although taking allot of time to

make, was worth all the effort.

Peter Tighe has just bought a

mark 11 Midget (which needs mucho time & effort to restore i.e.. it's

pretty rough!) & the radiator was on it's last legs. Rather than waste

money on recoring the radiator, he went straight to this unit now. Why

bother, well the plan is for a supercharged Metro engine to be fitted &

he has already started collecting the necessary parts.

The core was ordered with a

large overhang header plate on the 57mm dimple wall tubes. We also had

the fin spacing made courser to help the 12" Davies Craig fan pull

enough air through. This is my only concern with this radiator& it

caused us to spend 6-7 hours testing actual air flow with different fan

& core combinations. I have done allot of tests in the past, but not

comprehensive back to back testing of all fan/core combinations at

engine voltage.

Swedges were added to tank for

strength more so than looks, as the oe. tank is prone to cracking from

flex in this area.

To me, the radiator has a real

original look, but is high performance custom at the same time. The top

tank retains the original profile but has been cut down in height to

allow a taller core to be used, not only for more efficient cooling, but

also for a 12" fan to be fitted. |

|

|

Craig Able asked us to make a

radiator for his girlfriends Gemini. Not just any Gemini either, a two

litre twin cam engine providing the urge. We fabricated a dual pass

unit, as the engine has both

inlet/outlet hoses on the same side, making for both a more efficient

radiator & a much neater look. to me cross over pipes or hoses look ugly

& stand out, so we try to avoid them if at all possible.

We made the core 400 mm high to

mount a 16" Davies Craig fan neat & strong to the core & provide excess

air flow. Because this core has a much larger surface area than oe., we

used a two row 37mm thick core.

Close up of weld quality & our

new sheet metal recovery radiator cap fitted. |

|

| |

|

|

|

from Sydney wanted some extra cooling for his modified SV5000

Commodore. We welded mounts for the electric fan to the bands to save

him using the quick through the core type fasteners, which are a no - no

with alloy cores. He also wanted to keep the auto trans cooler, which is

a good idea for winter, remembering the water temp will be cooler in

summer.

wanted to run his cold air induction which screws onto the center rib of

the bands, so we incorporated a rib that we normally don't worry about

Quality in all our work!

|

|

|

We Have

fabricated a couple of FJ Holden radiators now, this one belonging to

from Caboulture, for his much modified Ute. It sees use on the street &

strip & because he wanted to run the engine fan, a 37mm 2 row core was

used.

Geoff Wright Kelly

from Bracken Ridge has a trick Holden FJ Ute he uses for shows & also

street driving . The core as made a bit taller than oe. to give an

increase in cooling & the top inlet pipe was moved further to the side

to give better water distribution through the core. We

A small filler

neck had to be used because of the width & radius of the top tank.

Recovery bottle

with Speedflow fittings, was welded on to make one unit.tank's small

filler

|

|

|

Dennis Walters from

Toowoomba has built a very tough, show class winning, TF

Cortina Station Wagon. It runs a 250 cu.in. Straight six, EFI. and

Supercharged, so Dennis wanted to have a cooling safety margin with

the engine, so asked us to build him a Radiator to suit.

Two rows of tubes 57mm thick, a

little wider core and narrower tanks than oe., for more cooling again.

We had to extend the flange for the water way back, as clearance with

the blower belt is tight in this area. Also welded a tube into the top

tank for the fan capillary tube sensor, doing away with having sealing

hassles under the hose!

Made a reinforcing bracket to

support the weight of the Davies Craig electric water pump Dennis

has been running. Please note our welding quality

|

|

|

Kris Kaminski out of

Adelaide wanted a radiator for his Mazda RX2.

When he gave us the measurements we had to work with, we had

bugger all width. This is not as much a problem with a Rotary as both

inlet/outlet are on the one side, so we had the more efficient dual pass

design to use.

We had to go two rows of big

tubes, 57mm thick, & to give enough surface area, minimize the size of

the tanks. Inlet/outlet tanks have to be a set ratio (or higher) to give

a reserve of water for the pump to pull & to distribute evenly across

the tubes. The other tank only has to worry about distributing the

water, so it can be very slim. By stepping the header plate back as we

have, the tanks can be made even slimmer, as they serve as a reservoir.

The tank may look too slim, but in fact it has 393% more cross sectional

area than the -16 weld on used, & 148% more than an 38mm oe inlet pipe.

Note step back in header plate

for water volume, two x -16 inlet/outlets & one x -04

breather used. And off course, our workmanship.

|

|

Pic of the bottom of

the Mazfix radiator in there modular unit. Even though it will

never be seen, we try just as hard with our workmanship.

Click here to link to the rest

of the modular assembly.

|

|

|

Jason from Rotary Automotive

Services in Adelaide ordered a modular radiator/oil cooler off us for an

atmo 13b in a RX2.

Big cooling benefits for both

the engine coolant & engine oil here. Not only does it look good, but

the more stable temperatures make for both more overall horsepower as

well as less wear & tear on mechanical components.

This is the most efficient

radiator design with both inlet/outlet are on the same side, as long as

there is big enough window for the flow rate, that is. The water has to

pass twice through the air flow & even though it is traveling faster,

the whole window of the core is more evenly used by the water -- more

evenly distributed through the tubes.

Once again, the pride in our

workmanship.

|

|

|

|