|

Anit-Freeze Who Needs It???

Applications for Anti-Freeze in Australia

As soon as someone says Anti-Freeze the immediate reaction from most people in Aus-

tralia is, who needs it. The facts are that a large number of vehicles can benefit from

anti-freeze in Australia as there is far more to Anti-Freeze than the name implies.

Anti-Freeze concentrates should really be looked at more along the lines of a complete cooling system

treatment with the added benefit of freezing protection. Tectaloy Anti-Freeze concentrate is formulated

with the best inhibitor packages and anti-foam agents available. Apart from depressing the freezing

point of a cooling system Tectaloy Anti-Freeze raises the boiling point of the system. Combine the higher

atmosphere boiling point of Anti-Freeze with the increased boiling point exerted by the radiator pressure

cap and you end up with quite substantial increases in the temperature a vehicle can run at before boiling

will take place.

Anti-Freeze concentrate also has the advantage of allowing you to mix a cooling fluid that will meet your

specific needs. Tectaloy Anti-Freeze comes with a mixing chart on the bottle so you can decide what

temperature protection level you need. Anti-Freeze concentrate is also very economical to use in some

cases where a good quality inhibitor package and freezing protection is required.

One point often overlooked is a phenomena known as wind chill factor. Wind chill is induced by moving

air, the faster it moves the colder its effect gets even though the ambient temperature is stable. The chart

below illustrates the effect of air speed on temperature.

|

Actual Air Temperature |

Wind Speed |

Effective Temperature |

0 Celsius

0 Celsius

0 Celsius

0 Celsius

0 Celsius

0 Celsius

0 Celsius

|

O0 km/h

-O0'C

08 km/h

-02' C

16 km/h

-14' C

24 km/h

-21 ./C

32 km/h

-27" C

48 km/h

-34"C

64 km/h

-37" C |

Wind speeds above 64 km/h have very little further effect on the wind chill factor.

|

As you can see from this chart, if a vehicle was parked in an area where the surrounding air temperature

was 0ø Celsius and a wind of say 24 km/h came up, blowing directly through the radiator, the propensity

for the cooling fluid to freeze quickly is drastically accelerated.

Wind chill needs to be considered in colder areas of Australia.

The Importance of Coolant pH Readings

NOTE: pH readings are no more than just an indication of how acid or alkaline (caustic)

substances are. The pH of a cooling system fluid is quite simple to read with either a small

electronic pH meter or litmus paper. Litmus paper is considered to be a little less accurate,

but will give a good indication.

pH readings go from 1 to 14, 1 being extremely acid and 14 extremely alkaline (caustic), pH 7

is considered neutral and is neither acid or alkaline.

The table below shows the pH ranges considered normal for the majority of coolants and

corrosion inhibitors running in vehicle cooling systems

|

Ph Value |

Opinion |

1

2

3

4

5

6

7

8

9

10

11.

12.

13.

14.

|

Extremely dangerous, Raw Acid. Replace coolant immediately.

Extremely dangerous, Strong Acid. Replace coolant immediately.

Extremely dangerous, Acidic. Replace coolant immediately.

Dangerous, Mild Acid. Replace coolant immediately.

Unacceptable, Mildly Acid. Replace coolant immediately.

Unacceptable, Mildly Acidic. Replace coolant ASAP

Questionable, Neutral. Probably not functioning. Replace coolant.

Acceptable.

Acceptable.

Acceptable, Alkaline. Some coolant inhibitor systems function very well at

this pH eg. GMH specification HN2043 coolant.

Unacceptable, Mildly Alkaline. Replace coolant.

Dangerous, Highly Alkaline. Replace coolant immediately.

Extremely dangerous, Highly Alkaline. Replace coolant immediately.

Extremely dangerous, Caustic. Replace coolant immediately.

|

Conclusion:

The normal running pH scope for coolants and corrosion inhibitors falls between pH 7.5 and pH 9.5.

There are inhibitor systems that can function outside of these parameters but they are in the minority.

The manufacturers of the coolants and inhibitors should be able to tell you the acceptable pH ranges

for their products.

PRESSURIZED BOILING POINTS OF GLYCOL SOLUTIONS

NOTE: The following chart gives the boiling points of Ethylene Glycol solutions under pressure.

Pressure ranges covered are from 0 - 300 kPa (0 - 45 psi). In the automotive cooling system the

pressure exerted by the radiator pressure cap usually falls between 75 - 100 kPa (11 - 15 psi).

Boiling points of all radiator fluids increase with pressure, even water has a much higher boiling

point in a pressurised radiator.

|

Pressure |

Boiling Point Celsius |

|

kPa |

psi |

33% |

55% % of Glycol |

0

25

50

75

100

150

200

250

300

|

0

3.7

7.4

11.0

14.7

22.1

26.4

29.4

44.1

|

104.5°C

110.5°C

116.5°C

121.0°C

125.0°C

132.5°C

139.0°C

146.0°C

149.5°C

|

108.5°C

114.0°C

119.5°C

125.0°C

129.0°C

136.0°C

142.5°C

150.5°C

156.5°C

|

A faulty radiator cap can cause major overheating problems in a vehicle. Always pressure check

the radiator cap for correct pressure release. If the pressure is low the vehicle will boil and 10se

radiator coolant prematurely. If the pressure release is too high the radiator or radiator hoses

can split or burst. Also check the centre vacuum valve in the cap, as the modern vehicles,

coolant recovery system will not function if this valve is faulty.

SPECIFIC GRAVITY TABLE OF GLYCOL SOLUTIONS

NOTE: Specific gravity can be used to test the approximate formulated glycol content of a vehicle's

coolingsystem. The readings below are taken at 20ø Celsius. Temperature of the fluid is important

as the specific gravity of a glycol solution falls substantially as the temperature rises.

|

Percentage of Glycol |

Specific Gravity g/cm2 |

0 0.998

10 1.012

20 1.025

30 1.038

40 1.053

50 1.065

60 1.077

70 1.088

80 1.097

90 1.105

|

As an example of the effects of increased heat on the specific gravity results we will

take the most common Glycol / Water mix used in the automotive cooling system

(approximately 30% glycol to 70% demineralized water).

At 20° C we would get an S.G. of ............1.038

At 50° C ..................................................1.023

At 70° C ..................................................1.012

At 90° C ..................................................1.002 (Approx. vehicle running temp.)

At 110° C ..: .............................................0.996

At 140° C ................................................0.972

For consistency the cootant should be tested at a known temperature when using the

specific gravity method.

FREEZING POINTS OF WATER / GLYCOL SOLUTIONS

NOTE: The freezing points given below for Ethylene Glycol solutions are actually the

point at which the first ice crystals forms, not solid freeze.

Solid freezing, the point at which the fluid will expand and cause engine damage in the

form of cracked blocks or burst radiator etc, is quite a few degrees under these freeze

points.

|

Percentage of Ethylene Glycol |

First Ice Crystal Formation Celcius |

0%

-0° C

10%

-3° C

20%

-9° C

30%

-17° C

40%

-27° C

50%

-38° C

60%

-55° C »

68%

-73° C »

»»

70%

-62° C »

80%

-45° C

90%

-27° C

99%

-13° C

|

» These ratios can give significant variation when tested.

» », This is the maximum anti-freeze protection recorded. The recording should be

considered unreliable, the general accepted standard is 60% glycol to 40% waterf0r

maximum anti-freeze protection, after this ratio the anti-freeze protection will

diminish.

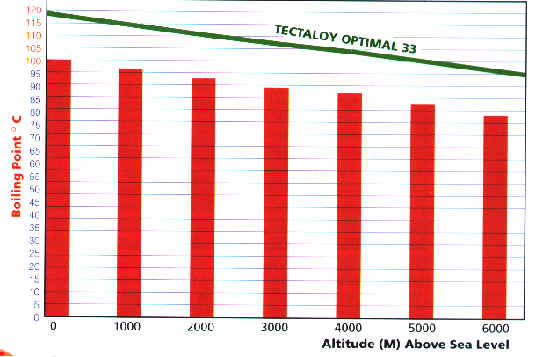

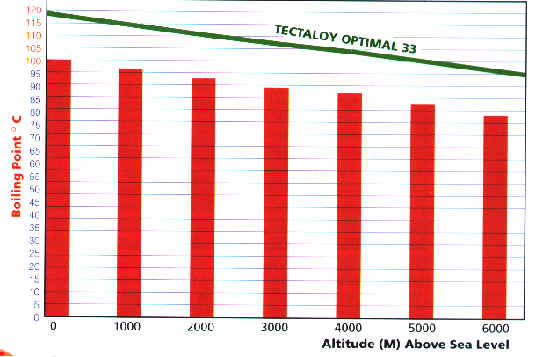

BOILING UNDER PRESSURE

There are two important factors that govern the

boiling point of a vehicle. The first is the saturation

boiling point of the cooling fluid and the second is

the pressure that the fluid is under. As a very rough

guide the boiling point of a cooling system is raised

by 1 o C per 5.5kPa of radiator cap pressure. From

this calculation we can see the boiling point of a

cooling system with a 100kPa radiator cap would

be approximately 118ø C.

A fact that is often overlooked when mechanics

evaluate a cooling system is the internal running

temperatures of the cooling fluid, it is not unusual

to have coolant temperatures exceeding 140ø C in

the hotter areas of the modern engine and a general

coolant temperature in the block approaching

130ø C. This means even with a 100 kPa pressure

cap on the cooling system, water just isn't up to

the task any more and will actually be boiling

viciously in certain parts of the engine. A good

quality glycol based coolant will compensate and

|

protect the cooling system from the effects of

accelerated hot spot corrosion.

As you can see from the graph below water does

not necessarily boil at 100ø C, its boiling point is

dependant on altitude. If you increase the pressure

on water you raise it's boiling point so reducing

pressure will naturally lower the boiling point of

water. The higher above sea level you go the less

atmospheric pressure is exerted and the boiling

point is lowered.

Should the cooling system's pressurization

mechanism become faulty (the spring loaded release

valve of the radiator cap), then boiling and after-

boiling will occur more readily at higher altitudes.

The radiator cap prevents the effects of high altitude

boiling as it keeps a constant pressure on the cooling

system. A good quality glycol based coolant like

Tectaloy Optimal 33 offers additional protection

against high altitude boiling as it has a superior high

altitude boiling curve.

|

(Disclaimer: All

information, graphs, tables, and specifications are the sole property of

Tectaloy® Coolants Australia and has been taken from Tectaloy: Cooling System

Products, More than just a coolant! (vol 2) © De Ville Australia 1996)

|