This

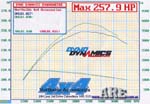

is 193kw @ rear

36" tyres! Wow ! This

is 193kw @ rear

36" tyres! Wow !

|

This dyno graph is from the May

Labour Day competition @ the 3 day Landcruiser Park

bash. If this hasn't caught

your attention, then you must be a petrol head with

no knowledge of diesel engines. To put it into

perspective, with the same big chunky 36" tyres &

the same diff., he has gone from 75.3kw. with the

top mount air-air, to 81.0kw ( 7.6%increase) with

our air-water, to 193kw (138%increase) with our

prototype air-water intercooler-plennum unit !!!

Obviously, there is allot more than our intercooler

involved here. He went to a tubular exhaust, ball

bearing Garrett turbo, tidied inlet ports & a very

special big $$$ fuel pump. All the work was

performed by Heath & Ian with product from

businesses in south east Qld.

These three pics are what I used

to convince the guys to go with an untried idea I've

had for years, & spend much more than they wanted

too. I had shown them the six pages of our computer

modelling programme with a few different scenarios,

& they knew that was very accurate from past

experience, BUT, there was two stumbling blocks. The

plennum was untried & I'm not that big into diesels

so didn't give any guarantees, & Ian said that he

could do a Chev V8 conversion for similar money -

valid. Heath pointed out that while a V8 could have

more power, it would never have the low end Grunt &

engine breaking of these diesels. I'd given them a

bloody good price as they were the 'guinea pigs',&

it would be two at the same time, so it was crunch

time. I clearly remember the guys talking it over

out at their car for over an hour, before coming in

& laying a deposit down.

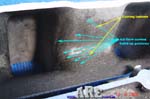

The carbon build up is a give away to the poor

factory design when the boost is raised. The blacker

the area, the slower the air speed &/or turbulence,

meaning those cylinders are not getting the same

amount of air. Three & four are clearly the lean

cylinders & will burn the pistons up early (or at

least dramatically shorten head gasket - valve -

ring life at best) at the tune levels these guys

wanted to go to. We also considered welding the

single entrie & making two entries into the oe log,

which would've been heaps cheaper, but I bet they're

bloody glad we didn't take that shortcut.

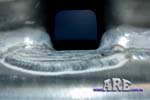

It's not the sort of job you get a

mate to do for a couple cartons. There's my thirty

years of air flow bench & 20 years of TIG welding

experience in this. I had to pad weld this part of

the inlet to get a very smooth transition with the

best transition angles. In fact, I picked up a

little flow on the second plennum, so cut the first

one off & did the same mod to it, at no charge. Not

many shops are that conciencious - or maybe I'm a

dickhead?

This is tricky welding, 3mm plate

butted onto 4mm plate of cladded alloy, 4 mm from

0.03mm fins & it has to be a full penetration

weld as it has the full weight of the cooling matrix

hanging off it.

Trial fit up during fabrication to

make sure everything lined up. The engine is

swallowing over 900 cfm now, & with the chunky tyres

throwing rocks, dirt & dust everywhere, filtering is

paramount. I just can't stress this enough. That's

why we fitted such a big K&N pod filter & our own

easily replaceable foam pre filter that slides in

the mesh near the entry.In a sense the inlet track

is 20mm long as that's the total of length between

the turbo outlet & tank inlet. How much lag?

Compared to a front mount it's almost unmeasurable.

Even though our plennum is 478% larger than oe., lag

is heaps less than a front mount instal

850rpm,

2500rpm,

4500rpm

- front mount & pipeing -

0.691 sec

0.235sec

0.131sec

- our air water/plennum assy.-

0.499 sec 0.169

sec

0.094sec

the above figures are from are computer modelling

Lag programme. They are how long it takes a molecule

of charge air to travel from the compressor housing

outlet to the valve head, at the rev. stated & if

the pipes are straight. There are far too many

variables to be able to calculate accelerating lag

as you can see it is exponentially quicker as revs

rise.

This is the end result on Heaths

truck. He kept the same radiator( which will

struggle on a long straight on a hot day), & of

course, the Davies Craig EWP will handle the flow

easily.

Apart from cost, the only other problem could be

longetivity, with so much weight swinging off the

top of a vibrating engine & then being pounded be

such rough use these guys throw their trucks at! We

have done everything possible with both materials

used & fabrication skill & tricks for the longest

life possible. The air speed in the short 63mm pipe

connecting the compressor housing to the the ic.

inlet tank is 254kph! We're now pulling 63kw (3583

BTU/m)of heat out of the intake charge, allowing

their other engine mods. to achieve the impressive

power output. They're good turbo petrol engine

specifications, but then I'd love to see this engine

in a 1400 kg VL Commodore beside allot of imports at

the lights! It would have similar power to a HSV 300

kw Monaro, less weight, & don't even think of how

much more torque !! What a burn out weapon - mega

grunt at any revs.

The air speed in the 4" snorkel is

92kph! so you can see why I talked them into such an

elaborate air box - it's necessary at this level

believe me. |