|

In July 2003 we increased

the parameters substantially & added a few new fields to

our in house developed computer modelling programme for

air water intercooling. We had only logged data

from 420 rwhp but we had already refined the programmes

accuracy to the point of being sure our figures

would be very close in the real world. After much

heartache, pain & money, it all came together for Craig

& Rob at the '08 Nats (yes - 5 years) & although

they didn't make the 2000hp, just on 1900rwhp has

vindicated the accuracy of our programme.

I do not know of any other

fabricator / manufacturer that has a programme anything

like this. We can accurately predict the results of our

air/water intercoolers fitted to your vehicle, so you

can have faith in knowing what the results are going to

be before you spend your money. Please check the

original '03

PDF

file below. |

SUMMERNATS 2008 HORSEPOWER HEROS

|

Note 1

Note 1 |

|

| Third - Gary Pope

-

BLO 402 -

1529rwhp |

First - Craig Munro -

Try Hard -

-1895rwhp

-

note almost overlay of back to back power curves |

Second - Lyle Lemmon - Mr PSI -

1713rwhp |

Note 1 - the sudden drop

off in power at 192kph is a boost loss issue that is suspected to be

blow off valve related, as the valves control the boost - now being

changed too waste gates control as mid 30 PSI is the maximum boost

available with the setup as run here ! The run was on track to make

even more power !!

The above three cars have a number of

things in common.

All the above graphs were achieved in a room @ 36°c & are rear wheel

horsepower.

They are owned by dedicated enthusiasts.

They were mostly built by the HorsePower Factory

www.hp-f.com.au -

overseen by Rob Vickery.

They were all tuned in house by Amberley Autos

www.amberleyautos.com.au

Their intercoolers were computer modelled & then fabricated by ARE

Cooling .

The owners are now much poorer than before they started.

| KPH |

RWHP |

HP diff. |

% dif. in 2 |

HP inc. |

RWHP |

HP diff. |

% dif. in 2 |

HP inc. |

RWHP |

HP diff. |

% dif. in 2 |

HP inc. |

| 100 |

185 |

- 10 |

- 5.4% |

|

230 |

20 |

8.7% |

|

205 |

15 |

7.3% |

-- |

| 110 |

200 |

- 20 |

- 9.5% |

|

270 |

40 |

14.8% |

|

260 |

10 |

3.8% |

26.8 |

| 120 |

225 |

- 25 |

-12.5% |

|

320 |

40 |

12.5% |

|

330 |

5 |

1.5% |

26.9 |

| 130 |

270 |

- 40 |

-17.2% |

|

400 |

60 |

15.0% |

|

430 |

5 |

1.2% |

30.3 |

| 140 |

305 |

- 40 |

- 9.4% |

|

535 |

110 |

20.6% |

|

585 |

20 |

3.4% |

36.0 |

| 150 |

370 |

- 60 |

-15.3% |

|

745 |

190 |

25.5% |

|

740 |

15 |

2.0% |

26.5 |

| 160 |

490 |

- 80 |

-16.6% |

|

1065 |

210 |

19.7% |

|

880 |

15 |

1.7% |

18.9 |

| 170 |

690 |

-170 |

-21.4% |

|

1340 |

120 |

8.9% |

|

1005 |

5 |

0.5% |

14.2 |

| 180 |

1000 |

-200 |

-18.2% |

|

1530 |

150 |

9.8% |

|

1340 |

5 |

0.4% |

33.3 |

| 190 |

1175 |

-110 |

- 8.4% |

|

1645 |

110 |

6.7% |

|

1710 |

20 |

1.2% |

27.6 |

| 200 |

1430 |

- 65

|

- 3.9% |

|

1645 |

110 |

6.7% |

|

1820 |

90 |

4.9% |

6.4 |

| 210 |

1460 |

- 20 |

- 1.1% |

|

1600 |

100 |

6.3% |

|

1630 |

350 |

21.4% |

-10.4 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

To be continued

This was originally uploaded to our site in late 2004

!

WhaT'S

the big deal

with this car ?

near standard

'sorta' standard

very standard

download the Summernat's 08 run here (right mouse click and save as)

M A Y B E 2000hp

(1500kw)

???

Please note that this

is what our system is designed for, what owner - Craig Munro

www.hphero.com

would obviously love to make, what crew chief - Rob Vickery is aiming for

& what we're all hoping Amberley Autos/Horsepower factory

www.amberleyautos.com.au Marty can tune this beast to. The biggest

worry in this equation is the Pump fuel - 98 ron. I have no doubt in my mind

that these power levels are obtainable with C16 or equivilent, but optimax is

going to take an exacting level of tune & cold charge air.

M A Y B E

T H I S ! ! !

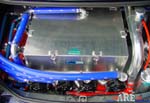

Note that hoses are colour

coded throughout the car.

Red is Heated water.

Blue is cooled water.

|

|

|

|

|

Equal amounts of chilled water into both sides of the intercooler. |

The blow off valve is nearly as big as some cars turbos ! |

|

This is the ice chiller. The boot is the only area big enough to

hold enough ice to absorb the heat from the front a-w. ic. |

This is the underside of the ice chiller box lid. All hole positions

& sizes are calculated - not guessed. |

I reckon the unusual mix of speedflow alloy AN fittings on SFS

silicon hose, that we pioneered, looks real trick. |

Cold water in the blue hoses in & hot water out the red hoses out. |

|

4 DC. engine water pumps push minimum of 180l of chilled water up to

the engine bay. |

3 SX fuel pumps push fuel up to the engine, Thru our ice chiller

sump. |

|

|

|

|

|

Definitely not your average cooling system. Curved rad- iator is to

allow air from 3 fans to escape. |

We used a mixture of alloy tube & silicon hose for best water flow. |

|

With the cover on you'd never know what's underneath. |

These three D.C. pumps are to recirculate the ice chiller water

only. Need 150 l / m. flow. |

3 silicon hoses in centre carries very cold water & single hose on

right, bloody hot charge air. |

|

|

When the side skirts are fitted, this is all that can be seen to get

180 l/m. of water from the boot to the engine bay. |

The side pipes had to be welded in an oval shape to allow the side

skirts to fit. |

Link to our new

DRY ICE RACE intercoolers

and

T H I S is

how we made it

!

A six page PDF file |

This is the first stage of the

project. It is the PDF file of our ARE computer

programme sent to Rob & Craig with the projected results of the system

we designed. This was July '03. Not too long now before we know how

accurate it is! We use a ±5% allowance with our temperature.

Please note: There are hundreds of lines of calculus that are

hidden in our programme & the solid coloured cells are to prevent cross

referencing of data in different files on our site. There's more here

than I should give away anyway. |

|

This is the second stage before we

attack any alloy. Cardboard templates to make sure it's all going to

fit. As it turned out, the top two matrix had to be reduced because of a

four mm. interference that we could not get around |

|

|

|

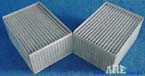

These are two of the eight core

matrix used in the intercooler. They are our brand new tube extrusion

that delayed completion of the car. |

|

|

|

They may look straight forward, but

there is a total of at least 25 hours work in this tank , &

both would have to be different ! |

|

|

|

It took 3 times on the flow bench to

get the distribution pattern I wanted Yes, it does cost pressure drop,

but the cooling gain far out- weights this. Every joint is double welded

for strength. The start position & profile of the baffle is most

critical. |

|

This is the battery box we had to

fabricate. |

|

Seamless transition from the mandrel

bend to the tank roof. The external fillet weld pattern is left

because it has nothing to do with performance & can't be seen. There is

a limit to wasting time. |

|

Craig wants to be able to take his

mates for a skid in comfort & wouldn't let us run 2x2½" water pipes

through the cab, so we had to do this. Added a few grand to the price,

so I hope his mates enjoy it - they're eyes will be tennis balls |

|

Nothing about this job was straight

forward. Maybe a spray pattern is overkill, but it all helps. |

|

These are the fuel pipes running

through the ice box sump for extra cooling. |

|

This sucker should remove 410kw. of

heat out of the intake charge. The air speed thru each inlet pipe is 205

kph, but we've got it down to 29kph thru the core !! |

|

|

|

The water out of the two bottom

cores, is going to be at a minimum of 104°c ! They will remove 79 kw of

heat each. Note: the last 2 cores (top) only remove 8kw each. |

|

|

|

The pipe shape is to fit everything

in Same for cutout in water tank. Id of every pipe is calculated for the

right flow rate. |

|

|

| |

|

|

Shows the curve we had to put in the

Radiator core to fit in the front This car has to cruise! |

| |

|

|

So naturally the fan shroud curve

had to match. |

|

When I saw this on my welding bench,

I just had to nick name it 'the fat arse cooler' ! It wouldn't

fit into even my pants. |

|

Finished fan shroud-fan assembly. 3

x 14" DC. fans provide 3324 cfm of ambient air flow. Oh, be wary of some

of the figures claimed. We've tested heaps !!! |

|

These are just two of the many pipes

we had to fabricate for this car. |

|

Some of the work we had to do on the

thermostat. Yes it has to run one - definitely! Same as every modern

car. Since alloy heads came in. |

|

This is the bracketry we fabricated

for the intercooler bottom mount on to the chassis rail. It has to

support a dry weight of 48kg. |

|

Finished thermostat ready to fit. |

|