|

Before we start, remember

that almost every motorized component is a compromise to some extent.

Adding an intercooler to your super/turbocharged engine costs power &

throttle response whilst in vacuum & very low boost!

Fit an intercooIer to a naturally aspirated engine & see what it does to

the power output curve. For a couple of decades when nearly all

competition & modified street engines in Australia were naturally

aspirated, opening up the ports or at least matching them with the

intake manifold was almost mandatory. So we worried about a small

mismatch of usually no more than 0.5mm. then, but some people now buy a

great monstrous chunk of alloy that tortures the same intake charge (&

isn't cheap) without much thought at all ! An intercooler causes a

static pressure drop across the core because of the extra

resistance of the Intake charge "rubbing" on the internal walls of the

"tube" & cooling "fins/ribs" create. This can vary between

approximately 0.3 to 5.0 psi. static pressure drop. The trick is too

cool the intake charge the most, with the least static pressure drop.

The more temperature that is pulled out of the intake charge, the higher

the dynamic pressure drop has to be, because the cooler air is denser &

occupies less volume. Simple physics. To judge a core properly on

pressure drop, you have to know the static pressure drop & subtract it

from the dynamic pressure drop, with the higher resulting figure

indicating a more efficient core - the exact opposite to what you may

first think. The denser the air, the more oxygen ( there is approx. 22 %

oxygen in the atmosphere, & it is only oxygen that will burn in the

combustion mixture), the more kw. produced. A rough rule of thumb is for

every 10° farenheight - 1% extra kw. is produced ! So even though it

does theoretically cost power with pressure drop,

the denser intake charge easily compensates for this,

with a power gain between not much to a bloody lot, realized !! The more

the charging device beats & heats up the intake charge, the higher the

power gains from intercooling & more importantly to me, the safer

(engine component life) the gains are made. No point in winning the race

back to the mechanic for a new headgasket , or worse, a new set of

pistons, each time.

The heat from the intake

charge is dissipated by contact with the surface of the interior walls

(fins or extrusions), and then it transfers through the thickness of the

"tube" wall to the surface of the exterior fin, from where it is

transported away by the passing ambient air flowing through the core.

It seems that due to the cost of new fabricated intercoolers, a lot of

people are looking for a cheap alternative. However, as the old

saying goes, 'you only get what you pay for' and usually the same

applies to intercoolers. There are significant differences in

intercoolers, not only in core construction (bar and plate or tube and

fin etc.), but also their design (especially end tank design).

There is usually a reason

for the cost involved in buying a new intercooler (whether it be ARE or

another company), and they do offer advantages over other options,

especially cut down truck intercoolers

ENGINE DESTRUCTION ! ! ! !

The most single deadly

forced induction engine destroyer (apart from no oil) has two common

names :- Detonation or when I did my time at college,

Pre Ignition. My interpretation of these is when the spark plug

ignites the intake charge, the flame front travels rapidly but smoothly,

across the piston face to fill the combustion chamber with the exploding

fuel charge & force the piston back down the bore. When something

happens to destabilize the smooth travel of the flame front (wrong

combustion chamber/piston dome shape, little/no squelch surface, sharp

edges, hot heat range plugs, advanced timing, excessive compression,

high boost, too low octane fuel,) one or more smaller fronts can start &

these then collide, resulting in an early &/or more violent explosion,

resulting in the knocking or pinging noise that sometimes can be heard

from the top part of the engine. Interestingly, it is easier to hear a

standard car/ute ( our terrible unleaded) pulling away from the lights

up a hill, than it is a turbocharged car. I have to admit that I lost an

engine of mine only this year, whilst testing on the open road

(steepish hill) without hearing it. Radio on low & passenger reading

data, I felt the engine nose over but by the time I clicked it & coasted

to a stop, it was missing on one cylinder - side gone out of the top of

the piston - expensive! That quick. Don't pass me off as a dickhead & it

wont happen to you, be aware. The boost gauge decided to read at 60% of

actual boost sometime just before the testing started, I adjusted it up

thinking someone had changed it & it's that simple.

The cooler the intake charge - the less chance you have of detonation !

I'm also positive that a consistently stable (air/water is supreme here)

cooler intake charge also increases the life of headgasket, valve &

seats, top bore-ring-ring land to a noticeable degree, whilst offering

considerable more power potential. How important is intercooler

selection now ????

Bar and Plate, Extruded Tube and Fin, Folded Tube & Fin or

Plate tube & fin?

115, 90, 75mm bar/plate on left & 73, 57, 3mm

tube/fin on right. |

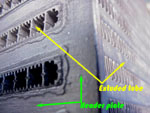

Close up of bar/plate (heavy) on the

left & tube/fin (tough) on the right |

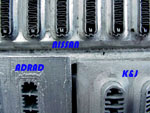

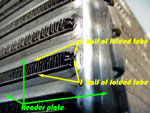

Nissan folded tube & fin on top. Adrad on left

& K&J on right bot. - both are extruded tube - tough. |

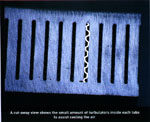

Denso plate tube & fin. Too many seams + too

weak. Usually small thinner tubes with close fine fins. |

|

The intercooler cores

produced by both manufacturers in Australia are extruded tube & fin

design. There are actually 4 manufacturers of aluminium radiator cores

in Australia - ADRAD in Adelaide, DENSO in Melbourne, K&J in Currumbin &

NATRA in Melbourne - but only two of these will make a core to size

(npn) & it also happens that the same two are the only ones too

manufacture intercooler cores - ADRAD and K&J ! A variant of the

extruded tube core is the folded tube core, which has two thinner wall

sections with a seam folded to the inside, manufactured by Calsonic in

Japan & fitted oe by Nissan - including the GTR. Bar & plate is most

common in the USA. aftermarket (& strong in trucking industry), whilst

the plate tube is common in oe. intercoolers in Japan - mostly Denso -

Toyota & Diahatsu, & a couple of Mazda models. Japans aftermarket

is more tube & fin than bar & plate when looking through the catalogues,

with no aftermarket performance plate tube & fin cores from any country

- thank goodness.

AIR FLOW.

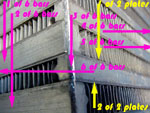

The above pictures show how in all the different

intercooler design/production methods, one basic feature is common

to all - the Ambient air flow is at ninety degrees to the Charge air

flow.

AMBIENT AIR FLOW

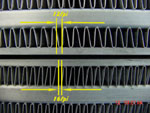

Tube/fin top core & bar/plate underneath.

These are average fin pitches, but if needed, we vary them to

suit the purpose. |

Our bar/plate top & Garrett below. Ours does

not have as close fpi & being neat, allow more air through to

the radiator |

May 2002 HOT4's - tiny tubes with large

ambient fins like this should only be for an air water

application |

May2002 Hot4's -super wide fin spacing like

this could only be for extreme high cfm @ low temperature,

or cheap ! |

Adrad tube. Ambient air brakes off back of

tube good.

|

Denso tube. Air brakes off back of tube good.

|

Garrett tube. Air brakes off back of tube

okay.

|

K&J tube. Air brakes off the back with highest

drag, negating the benefit of best entry performance

|

Tube & fin cores penetrate

the ambient air (channel the cooling air) better - less disturbance -

than plate tube & fin cores which penetrate just better than bar & plate

cores. Remember that in front mount applications, this has a small

effect on the engine water temperature, by slowing the air speed &

volume, before it reaches the radiator. This is because the rounded

leading edge of the extruded tube parts the air with less turbulence

than the "W" shape of the plate tube & fin core, only because this core

has thinner tubes than the other two. If the square leading edge of the

bar & plate tube was as thin as the plate tube, then it would flow

better, but it comes a close third. The above drawings illustrate the

turbulence caused by the three tube shapes. Please note that with the

leading edge of intercooler tube shape, we are talking very small

differences between them with tube pitch (spacing) having more effect

than tube shape on ambient air flow, and it has little effect on charge

heat dissipation, actually having allot more of an effect on radiator

cooling efficiency.

One point often overlooked is the body work across the front of the

vehicle. Modern car designs have evolved to aerodynamic swoopy

nosecones, which look great & give low drag coefficients, but make

intercooling & efficient engine system cooling, much more a science than

a few years ago. Most of the current designs rely on a low scoop just in

front of the radiator for the majority of air flow, so this has to be

taken into account when mounting the intercooler. The less direct path

the ambient air travels to the intercooler, the slower it's speed & so

it's ability to force it's way through the core, resulting in both core

thickness & fin pitch choice being much more important. Surface

area should be increased to compensate when core thickness &/or fin

pitch are reduced & ducting fabricated to channel all air possible to

the core & then through the radiator. . The same goes for Cars/four

wheel drives that have driving lights, winch etc. mounted in front of

the grille.

CHARGE AIR FLOW

Below is what the intake charge see's.

Tube/fin core Picture - Driftking |

bar/plate core Picture - driftking |

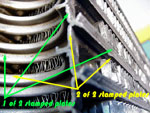

Much more important (to performance) than the ambient air flow

disruption is the charge air flow disruption entering the core flow

passages. Least effected (as manufactured) is air entering the plate

tube & fin core as the plates are stamped with a small radius as part of

their construction & the fact these tubes are always allot narrower,

however, check the paragraph on tanks before getting too excited.

Bar & plate cores are next, as the top surface is flat with a sharp 90

deg. edge. Tube & fin cores (both types) are definitely the worst as the

tubes are proud of the header plate causing some of the charge air

to do a 180 deg. turn at the plate then another 180 deg. turn to enter

the tube. Allot of turbulence/drag/static pressure drop! Most

manufacturers of these cores take the safe/fast way in production & cut

the tube lengths longer than necessary, hurting air flow, but knowing

that the product is integrally sound. The tubes usually stick up around

3-4mm, which makes the air flow do 2 distinct 180 deg, turns. The cores

out of the new Adrad factory are no more than 1mm proud of the header

plate, so they have really tightened up there production tolerances.

ARE. has a "venturie plate" option that gives the air flow a proper

radiused entry into the tube, increasing air flow by approx. 8.4%. @

10psi., an extremely worthwhile gain,& the only manufacturer I know of

doing this ! Once again Lateral thinking & R&D gives our customers an

advantage.

To size an intercooler properly, the most important

factor is what I call " the charge air window". This is the

surface area of the tubes for the charge air to enter. With cores from

the same manufacturer, just multiply the core height by the thickness,

but too compare cores from different manufacturers properly, you must

work out the surface area of each tube (allowing for fin/ribs etc.) &

count how many tubes in each core. The window controls two parameters, -

the pressure drop of the air entering the tube, so if he window is too

small for the cfm flow, the pressure drop increases. Most importantly,

if the window is too small, the air speed through the core will be too

high & not allow enough time for the heat to dissipate out of the

charge. If you play it safe & go too big in the widow size, then the

tube length needs to be kept short, or pressure

drop increases for little extra cooling. Best way

is too size the intake window for the cfm. requirement, then the length

of the tube for the heat dissipation requirement. That is for the same

kw. output, a larger turbo needs a larger window & a smaller turbo needs

a longer tube - generally.

COOLING CAPACITIES

(following some very

contentious paragraphs)

As a general rule, with a level playing

field (manufacturing quality, both fpi's, tube size, thickness, & a

hundred other variables), bar & plate intercooler cores dissipate more

BTU's than plate tube & fin & then tube & fin cores - per square

centimetre. Please stop, go back & read that sentence again, as it

is the most often asked question, but the most misquoted answer of all

time. Please also note that it is very easy to change just one

specification of a core to make it better than the other (forget plate

tube & fin here), & it must be remembered right now that heat

dissipation is only one parameter of overall intercooler performance. If

there is enough area & volume available, I mostly recommend a tube & fin

core to do the job, as it will get the temperature down close to bar &

plate, but at less pressure drop & less chance of leakage.

The most consistent method of charge air

heat transference is Extruded tube. This is because the aluminium is

forced through the extrusion die during manufacture, giving a 100%

wall to rib bond as there is no join in the material. The next most

consistent is the "square" shaped fin, as it is stamped with a flat

surface to fuse onto the tube wall, giving up too 10 times the surface

area to bond to the tube over the least consistent, folded fin, which is

the most common in bar & plate, & all that's seen in plate & fin cores.

We have seen intercoolers where the tolerance of the fin fold width is

too narrow & so the fin didn't fuse too the tube wall, resulting in no

heat transference in that area. Also the fins can bunch up, leaving a

gap either side, very inefficient. Another reason for the difference in

the price of cores - quality control against sloppy manufacture.

The most efficient method of Charge air

heat entrapment is folded fin, because louvered fin configurations &/or

very close fin per inch ratios can be utilized, resulting in higher

surface areas to "grab" the heat. Note that these also cause the

greatest pressure drop. It really comes down to manufacturing quality &

specifications between folded fin & extruded tube efficiency as they can

give similar results. Some folded fins have holes to break up the air

flow, some have louvered fins to channel the air & some are plain flat,

but they usually have higher fpi. ratios. Extruded tube dividing walls

are either flat or have ridges running length ways for increased surface

area.

Below are 5 pics of different bar/plate cores. You have to know all the

specifications to be able to accurately judge which core suits your

application best, Then there's tube/fin !!

Our 3rd. generation bar/plate on

left compared to best the same factory offered on right. Big

difference in performance. Both a larger tube & more fins = cool |

Top is narrower charge passage to

ambient ratio compared to bottom. Note bloody sloppy quality of

bottom core! We have to straighten fins before welding

tanks on. |

On the left is a louvered fin

(more cooling & pressure drop) & on the right is punched

fin. Different results. |

May 92 HOT4's shows ridicules course finning I

can't think of any application for this except cost. Not even

air/water. |

May 02 HOT4's shows three

examples of course finning which is inefficient, cheap, &

flooding our market. Be wary ! ******CHEAP

can mean

HEAT******* |

Three different bar/plate core from 2

different manufactures. Note the very small "tube" size for

water cooling in the air/water core. Also the courser fpi. of

the Spearco air/air core

|

There are some cases where I will

definitely not recommend a tube & fin core & they are where there is not

enough room for a properly sized core, usually upgrades in the oe.

position - Subaru top mounts, S13,14,15, Skyline GTS, 300ZX inner guard

etc. or big kw. applications. The thickest tube & fin core made in

Australia is 75mm & there are allot of applications where that will not

allow large enough intake window area size, causing a pressure buildup

in the inlet tank with the charge trying to get into the tubes & too

high air speed through the tubes, to be able to pull the heat out of the

charge. Note: This has now changed as of August 2002 with ADRAD

producing 109mm & 146mm thick tube/fin, & having instigated & played a

part in their development, I mostly recommend these cores except for

extreme cfm & heat applications ie: very large turbo's working near or

above their efficiency range, size not available or not enough room -

header plate size. It is impossible to repair a leak near the centre of

a thick core, & because tube/fin is both stronger & less prone to leaks,

they get my vote. I have not made any mention of the plate tube & fin

core, because to my knowledge, the Japanese plants only supply to the

oe. industry & do not sell to the aftermarket. For overseas customers, I

have seen thicker tube & fin cores made in Japan & I imagine these could

be a viable alternative.

An advantage of the bar & plate core

is when there is a lack of room situation in thickness at the tank ends,

as a tube & fin core has to have the outside of the tank at least 6mm

proud of the tubes on each side (absolute min. 87mm tank on a 75mm

core), whereas the tank can be a few mm inboard of the bar & plate core

86mm tank on a 90mm core). This can be very important in cars with short

engine bay/grille areas (Datsun 1600, Hi Lux etc.).

Note that usually, the more surface area,

the higher heat transference, but also the greater pressure drop. There

is no across the board, standout performer in the above three cores, as

they all have there strength & weaknesses, but it is a two horse race,

as plate & fin cores are only available oe., meaning smaller sizes for

lower kw. applications. They have too much static pressure drop & are

too weak to be manufactured in large sizes. You will have to add you own

interpretation to what the company you are dealing with has to say, &

hope they know exactly what they are talking about

Plate tube & fin tanks, for

charge air flow, are a basic disaster with the high capillary turbulence

caused by the approx. 240 deg. convoluted walls causing a large static

pressure drop. I have never bothered to measure the flow drop because

there is no point - only used in oe applications, thank goodness. Sorry

Denso, but that design is a shocker, it should be left to oil coolers,

if at all ! These must have been designed by accountants.

Core Construction

115, 90 & 75mm bar/plate on left. 73,57,37mm

tube/fin in right.

|

Our bar/plate on the left & K&J tube fin on the

right.

|

Nissan skyline oe on top. Adrad on left & K&J

tube/fins on right.

|

|

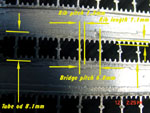

Real close up of the three different header

plate designs.

|

Difference in fins & tubes between K&J

closer & ADRAD cores, even though both are tube/fin |

The extruded tubes. Integral

strength over bar/plate. We remove any swarf before welding or

it's straight into your engine !

|

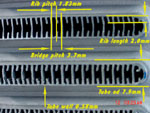

When I was in the factory, we

discussed rib size, flow tested the tubes & this is the result -

1.28mm ribs instead of .80mm

|

Plate tube & fin cores are the physically weakest core in that we have

allot more of them come through our workshop for repairs than any of the

other three, & too reinforce that, they usually have a larger leak for

the damage &/or the leak be further away from damaged area. The core has

three components too each tube. Two stamped side plates with fine folded

fins fused internally. I believe the plates are "stretched" too far to

form the tank on each end, thinning the alloy to where it will crack

with minor stress. They are clamped together (looking like a piano

accordian) & furnace brazed.

Bar/Plate & fin

cores are the second weakest, even though they are also the heaviest

with a couple of the thickest components. However this is the reason for

their weakness. The thin plate side walls have to fuse onto the thick

plate sides to form a "tube", with both of them having to fuse onto the

very thick bars to form the "header plate" for the tank to be welded to.

It is hard for these three differing thickness to be held at the right

temperature for the cladding to melt, ??

& fuse the surfaces together. This is where we see most of the leaks in

these cores, even from new in one brand. The charge cooling fins are

fused to the thin plate walls, meaning there are 5 components too each

tube, a reason that these cores tend to develop a series of weeps along

the "header" seam.

Folded tube & Extruded tube seem to be of similar strength although with

two tube sides, fine fused internal fins & two header plate joints,

folded tube should be weaker with 5 components. However, I have seen

both types of cores come in for repairs quite beat up & out of shape,

without leaking. Eventually the hot/cold & pressure/vacuum cycles will

open up cracks.

The Extruded tube core is possibly the strongest core as it only has

three components in it's construction, a tube & two header plates. It is

also the most consistent performing unit as the internal charge air

cooling ribs are one piece with the tube walls whereas the above three

cores have tubes with fins fused too them & if the specifications vary

in production for any reason ( & it does occasionally), then an area of

fins can exist where they are not in full contact with the tube wall,

bottling up the heat in that area. The same also happens with external

ambient finning, although this is common to all four cores & can be

found with a simple visual/physical check.

Header

Plate/tube joints, bar/plate joints

Bar/plate top & tube fin bottom. Note how the

header plate is proud approx. 7mm/side making a wider overall

'cooler. |

Same pair intercoolers from opposite

direction. difference is more graphic. |

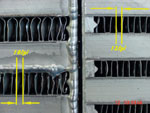

Folded tube/fin on top is okay, tube/fin

bottom left is best & right is worst for air flow entering tube. |

Bar/plate on left has intergral header plate,

whereas tube fine has to be proud to weld tank to. |

The 8 components that make a complete tube in a

bar/plate core

|

The 2 components that make a complete tube in a

tube/fin core. Note flux/cladding around tube.

|

The 3 components that make a complete tube in a

folded tube/ fin core. This has a tabbed header plate to hold

tank on.

|

The 2 components that make a complete tube in a

plate tube/fin core, including the tank - shown cut in half

here.

|

I have not worried about fin/ribs in the

above pics. as they are common too the internal structure of every tube

& would unnecessarily clutter the pics. They are highlighted in their

own section.

Finning

- or Ribs.

Both Adrad cores. Different fpi.'s for different

applications.

|

Adrad top & K&J bottom, different fin

shapes & pitches.

|

Garrett top & ours bottom. Straighter uniform

fin allows more air through.

|

Charge air fins, straight uniform fins allow

intake charge through with less pressure drop.

|

More open ribs of Adrad give 17% less pressure

drop. Radius on ribs adds to surface area.

|

Longer ribs help pull heat out of air better,

but more restriction.

|

Cut away bar/plate core shows fins at 90 degree

to each other, very efficient but high pressure drop.

|

This is actually an abient air fin, but very

similar to charge air fin. Louvers direct air flow but also cut

flow dramatically, so fpi important

|

The parts of

an intercooler that do all the "work" are the fins, or in the case of

extruded tubes, ribs. Their purpose is the opposite when in charge air

flow to ambient air flow. In charge air flow, their job is to soak up

the heat in the passing air & deliver it to the tube wall. The trick is

too pull the maximum heat out of the air with the least resistance to

flow. The different designs are flat fin (cheapest & least effective),

punched fin & closely followed by louvered fin (dearest & most effective

at heat soak but with highest pressure drop). Extruded tubes are formed

by forcing an aluminium block through a die resulting in a complex

one piece tube, offering 100% heat transfer between the rib & tube wall.

This does not always happen with fins, because sometimes the factory

does not apply the correct "crush" to the core when clamping in

assembly, resulting in no bond between the tube/fin during furnace

fusion. It appears to be more of a problem with internal fins than

external, but luckily, is not that common. Extruded tubes have internal

walls that form continuous compartments with ribs inside each

compartment. These vary between manufacturers, but the same rules apply

- more ribs/inch, more heat soak & pressure drop. Also the more ribs in

contact with the tube wall, the more efficient. Because of the extrusion

process, ribs are thicker than fins & there is always more open space in

the middle of the tube. This results in a small reduction in heat

transfer if the tube is too long, as the air " straight -ens out"-

reduces turbulence due to the smooth compartment & rib walls. With

Ambient air flow, the fins job is too radiate the heat, so the air

passing through the core absorbs the heat & transports it away from the

core - usually straight into the radiator finning - but that's another

problem! Adrad fold both fin edges over (hem the fin) which doubles the

strength fin & lessens damage. Damaged fins should always be

straightened as they inhibit air flow & so cooling efficiency. The

higher the vehicle speed &/or the more direct ducting to stop

spillage of the air around the core, the closer the fin pitch can be :-

an offroad buggy or hill climb car needs less fpi. than a circuit

racer. Some thought has to be given to radiator cooling or you can

create a problem that can limit the engine output more than the

intercooler can increase it! Intercooler position, surface area, fpi.,

tanks & workload, all have a bearing on engine water temperature.

TANKS - the single most underrated part of an intercooler !!!

|

This tank is extremely basic & because the outlet

is in line on the other tank,- even worse! |

This is our tank to do the same job So much more

efficient! How much more expensive? |

Line up of our Hot Chilli tanks. A couple of sizes

still to come. GTR type this end.

|

Note the over hang a tank has to have because of

the construction of tube/fin |

Not all cast tanks are created equal. We could

get our tanks cheaper, but we pay for quality/performance.

|

Our cast tank walls average 3.6mm thick,

negating heat soak problems assoc. with tanks that are 6 -7mm.

|

The areas between the lines are the "tanks" on a

Denso intercooler. The large boundary layer is extremely

turbulent causing a high pressure drop for no gain.

|

This is where allot of my knowledge comes from,

hundreds of hours testing but hundreds upon hundreds more

fabricating parts too test. Results do not always cross over to

the real world. Alex of Bryant Engineering.

|

The thickness of the alloy in tanks is very

important. Too thin & heat soak is negligible, but their life span maybe

short due to stresses from the continual hot/cool & boost pressure

cycling. too thick & they'll last forever, but suffer heat soak, which

is the time it takes the tank temperature to react to ambient &/or

charge temperature changes. Depending on the use of the vehicle, the

effect of heat soak varies. Constant high speed static throttle

position with a front mount (road transport) is the least effected. A

four wheel drive in soft sand or with a heavy boat up a ramp, fitted

with a top mount, is the most effected. We spent 14 months making

sheet metal tanks for next to nothing while I looked for a good pattern

maker & foundry. It's our customers gain as our tank walls average

3.6mm thick.

Shape or Profile

Most of the charge flows through the bottom 35%

of core, with the top 65% causing detrimental pressure drop

until high boost is reached. Worse again if other pipe is on the

bottom too !! |

The 2 corners cause large eddies & the

square inlet corners small eddies which restrict flow &

distribution across the core window. Worse if pipe is on bottom

other end !! |

Not perfect, but very good & very cost

effective. Nowhere near as important to have diagonally opposite

tanks like both designs on the left. Very small eddies & small

uneven distribution across core window |

Square shaped/edged tanks

are taboo for performance conscious enthusiasts for four reasons:-

1) They look basic,

agricultural & ugly

2) A square edge concentrates

stresses along that fold (or weld), which, depending on several factors,

will shorten the life of the tank to a some extent. It's surprising the

number of small weeps that can go undetected for months, especially if

the turbo seals are good (no oil stains), resulting in a loss of

economy/performance. This usually applies more to a sheet metal tank

than cast tanks, due to their thinner wall construction.

3) Most importantly is that

the square edged tanks hurt air flow & increase "static" pressure drop.

The intake charge does not want to make a sharp turn with the majority

of the air taking a radiused path around the edge, causing some of the

air to eddy back around through an elongated 360 degree tumble. This

causes friction with both the wall surface & the following air, really

hurting flow figures.

4) I don't know if any

manufacturers ever think of this, but when building tanks for a tube &

fin core, if more air is directed to the front or back of the tubes,

then that is how it stays for the entire length of that tube, as the

extruded bridge walls contain that charge & it can't mix until it

reaches the outlet tank, resulting in a cooling efficiency loss. With a

good bar & plate core (not a cheap plain flat fin) this can't happen

because the louvers or holes in the fins allow the charge to pass across

the "tube" as it travels lengthways. This problem doesn't apply when the

inlet pipe is inline (parallel) with the tubes & only applies a little

when big boost is being used.

In our Hot Chilli range of

tanks, the angles & radii of the triangulated roof are different for

each size tank. This is not a marketing gimmick, but shows how important

it is to get it right. Only three degrees sometimes made a difference of

2% of flow but 10% of window distribution.

Configuration

Two designs of tanks are very

poor in distributing the intake charge evenly across the core face.

Please note that 100% distribution is impossible, if the core is high

enough to offer worthwhile cooling.

One design is commonly used on

Rotary powered cars coming out of Sydney. The Core is 500+mm high & has

the inlet/outlet pipes in the bottom of both tanks at 90 deg angle,

parallel to charge flow. However the higher static pressure drop to

cooling efficiency ratio, is less important to a 20+ psi. drag car (it

will increase 'spool up' time! ), but decreases throttle response & a

few kw. output, in a street car. In the pictures (below) of our

answer to this problem, we have designed a dual pass intercooler that

splits the core area in half, so the intake charge uses the whole of the

core evenly. Attention has to be paid the the sizes however, as the air

speed through the core is doubled & if the charge window is too small, a

pressure build up (drop) will result.

4 of 9 tank shapes built to try to

maximize distribution across the core face.

|

From lower down to show some entry changes made.

Front 2 are absolute shockers.

|

In each tank we tried different baffle

shapes/angles & got some mixed results. Some hopeless.

|

In our initial testing, 80% of charge air used

end 25% of core at 264 cfm @ 25" water. Just turning bottom tank

around makes a big difference

|

If the outlet is below this inlet, this is the

worst combination I can think of. Step causes reversion, smaller

diameter speeds air flow & increasers syphoning !

|

This is the second worst combination I've tested

& it's so popular with the Rotary set. ARE has never sold an

intercooler like this - allot missed sales, but we now have a

better setup.

|

This is our solution too cooling the Rotary.

Maximum effeciency from this large core giving more cooling with

less pressure drop. Relocate the oil cooler & we can make it

even better.

|

Here is how our intercooler looks in the car.

Still fills up the front but gives more overall cooling with a

little less pressure drop. There is a limit to the cfm flow

through these cores & generally need to be thicker.

|

The other design mostly is

used in the USA., where tanks are on the top & bottom of the core,

causing the charge air to make two 90 deg. bends. By using a second

manometer with a long thin probe, we found that 80% of the intake charge

flows through the end 25% of tubes on our first test tank, which was of

reasonable length. Flow rate was good but cooling rate was terrible.

When we doubled the length of the tank, 55% of the intake charge flowed

through the end 25% of tubes & overall flow dropped 9%, indicating that

this design has too have very long tanks, but should be able to be

avoided anyway. We also discovered flow 'syphoning' for the first time

during this testing. The intercooler was making a strange noise, & with

the aid of the second manometer probe, & then removing the tank & using

the old tissue streamer on a stick trick, found that air was actually

being sucked back up the tubes next too the inlet end, by the same

principal as a spray gun operation. This means that some of the already

cooled intake charge was being recirculated through the core again. This

creates a double loss as not only does the extra syphoned air create

more pressure drop, it has already been cooled so takes away core space

needed by the hot air. I didn't waste time measuring the % recirculation

as we rarely use this design. Please note that this paragraph refers to

intercoolers with the inlet/outlet above each other (on the same side).

It is reduced noticeably if one tank is reversed, but still should be

avoided if possible. A dual pass intercooler is heaps more efficient

where both pipes are on the one side, but they require more height for

the core.

A few factors should be remembered

with air flow. Definitely don't polish the inside of tanks or pipes. An ultra

smooth surface causes capillary tension on the surface layer of air with the

wall & will increase drag so increasing pressure drop.

A street car is not in high boost that much of the time (maybe 10% max.- or no

licence, no tyres!), and for possibly 50% of the time in vacuum, with maybe

another 30% at less than 5psi boost, so the engine operates as a naturally

aspirated engine for approximately 70% of it's life. Now, how many hundreds of

hours a year do the Group A Supercar teams spend on the flow bench trying to

find even a half a percent increase in flow? A square edge tank can easily cause

a 20 percent drop in flow, at low boost driving !! Some people confuse the

result of poor tank/pipe design with turbo lag, when it actually may have little

or nothing to do with the turbo's performance. This has been reinforced with our

Air/Water intercooler R&D. program, where much shorter/straighter pipe lengths

are used (reduced "turbo" lag). A crisper throttle response with increased

"driveability" can actually be felt driving the vehicle, very important

not only on the street, but in Rally, Hillclimb, Gymkhana, Jet - boat, type

competitions. In my flow bench testing, I've found that making air flow change

direction by 360 deg. causes noticeably more pressure drop than a 180 deg.

change.

The importance of squared

tanks exponentially decreases as boost pressure increases, this is for

air flow & distribution. If you see a car at the drags that runs 35 plus

psi, with square tanks on it's intercooler, don't worry about it after

the car has launched & is revving out, as power loss is minimal ( maybe

3%), BUT, if the engine could not spool up quickly, or needs nitrous to

spool up, then the tank shape plays a very definite part in this

problem, with Rotary engines seemingly affected more than 4 stroke

engines. I have seen many drag cars, not being able too spool up onto

the converter for 1 to 3 seconds, usually mostly in the afternoon heat -

over cool night air, resulting in up to a quarter track lead to their

opponent. The importance of the inlet tank shape also exponentially

increases with the thickness of the core, from when it is 25% wider than

the inlet pipe, & especially for tube/fin cores.. The outlet tank

only has approx. 40% influence on this as the inlet. I have spent

hundreds of hours on the flow bench with everything from conventional

basic (opposition manufactureres) tanks, to some way out designs that

would be laughed at, but you can't always accurately predict the

results, & it's marvellous what I occasionally learn from these

experiments. I reckon 85% of my r&d. time is aimed at tough street car

applications to provide the most cooling with the highest horsepower

output with the crispest throttle response. Note the word economy was

not used, because it goes hand in hand with crisp throttle response.

Material

Not a pretty sight. Too thin material used. |

A closer pic of the thickness guage. We use 2mm

for hand hammered (formed) tanks without flat surfaces & 2.5 or 3mm

on everything else. |

Macro picture of 3mm sheet metal tank surface.

Fold made with 10mm dia. mandrel. Can see surface cracks if made

with sharp edge folder.

|

Surface of cast tank. Both polish up similar, but

cast takes longer. Can have inclusions or blow holes that will leak

if not cast proper;ly.

|

If the tank wall is too thick is it will become a

heat soak & counteract part of the advantage your intercooler provides.

Worst example is a thick cast tank fitted to a Subaru WRX top mount - or

any top mount. It is getting all the under bonnet heat (around 70°c.) at

low speed & then when nailed, takes a couple of seconds to drop to it's

proper temperature, which isn't that cool anyway. This has much less

effect on a front mount, except when reversing back after that big

impressive burnout & it won't stabilize when staging either. We pay more

for our cast range of tanks, but they average 3.7mm thickness & are well

worth it because of the formentioned problems.

Can an intercooler be too big?

YES ! In street driven

applications, an intercooler can definitely be too big, maybe not for

'attitude', but for maximum performance. It is not an argument to say

that Joe Blow's RX2 runs 9.6 @ 132 with a monstrous intercooler because

that car may run 9.4 @ 134 with an intercooler that is engineered very

close to the overall requirements of that combination. The same may be

said for Fred Nerks TX3 that runs 13.8 @ 100 with his headlight to

headlight monster intercooler jumping out of the grille. The car may run

13 flat @ 110 with a properly engineered intercooler/pipe setup. This is

because if a 13,500 cu. cm. core drops the intake temperature to 40° c.

@ 1.5 psi. "static" pressure drop, a 9,550 cu. cm. core may drop the

temperature to 41°c @ 0.82 psi "static" pressure drop, & I know which

will produce more power !

The closer to ambient

temperature the intake charge gets cooled to, the exponentially larger

the internal surface area of the core is needed, also exponentially

increasing the friction (drag) of the charge air in the larger core,

causing higher Static pressure drop. Please note that the same kw.

output can be generated by two engines, but require two different

intercoolers. If one engine is fitted with a smaller than optimum

turbo, then it will operate out of it's efficiency range, over revving &

'beating' the air, to a higher temperature. Even in a street application

40+ c. (eg. 120 to 160° c.) is common! This requires a more efficient

cooling intercooler, with either larger volume, more cooling fins or

longer tube length, than the other engine that is fitted with a larger

than optimum turbo, which may only heat the charge to 105° c., placing

less importance on the intercooler, but more on the inlet tank "window"

(area) which needs to be larger & the tube length shorter. The first

engine makes a better street driver, as the turbo will be on boost at

considerably lower revs.

A really important point is

that the more oversize an intercooler is, the more important tank shape

is, for both pressure drop & charge distribution across the core face.

Make an effort to suss out the best overall intercooler & pipework for

your car, usage & driving style. It will make a worthwhile gain, &

possibly at less cost!

Turbo Lag ? or is it

The internet is a great thing, BUT, there are so many false statements that

people make sound so convincing. "I put a big front mount on my VL Commodore

& there's no extra lag at all, it goes heaps better too". Treat this person with

total distrust. The only accurate (note: I did not say honest, because he may be

genuinely kidding himself) part is ' it goes heaps better'. It is a physical &

scientific impossibility, to not have extra lag in this case.

If it was a Skyline or similar car, treat the person with some distrust & quiz

them on both setups, as the system they replaced was certainly not optimized

&/or the new system must be totally suited to the car.

-- These figures are calculated for a system with

perfect air flow, without disturbance from poor tank shape, poor core flow

efficiency, gaps in pipes, no. & type of bends & many more factors, so the

actual real world times will be slower !

-- The actual times a molecule of air takes to travel the

system during , from idle, to 8500rpm., giving a total lag rate, cannot be

accurately

calculated as the variables are immense & will differ for every single part in

the application. From all our testing, I believe tank shape & pipe bends have

40% of the effect on lag rate compared to the turbo, on average of course. To

give you an idea of air flow, two pipe kits bent up on the same cnc mandrel

machine & then beaded by the same person, will not flow the exact same amount of

air.

-- These four graphs are to help you get a handle on how

important it is to run a properly designed system for street throttle response

or race car spool up. This is part of the reason a high stall auto, -turbo, -4

cyl. drag car is usually more consistent on the strip.

-- Note: -- The smaller the engine capacity - or the

lower the revs used - the more important the design is.

-- Boost has

miniscule bearing on charge air speed/time - it changes the cfm.

output, making the charge denser & hotter, BUT, not the air speed

velocity ! -

see fifth chart below.

-- The lights on an ANDRA Xmas start tree are 0.400 of a sec. intervals.

-- We have been using these figures (in house developed

computer programme) for years to help us design ic. systems for customers, maybe

that's why so many of our customers speak so highly of the results our products

provide.

-- Following are four PDF files to validate the above.

Pipes, Couplers

and

Clamps

I know they're not

intercoolers, but your shiny new $1000 piece of alloy lurking behind the grille

isn't much use without them. Pipes also have to be engineered or they can cause

sizeable pressure drops. The worst thing you can ask the charge air too do

is turn back on itself ie. make a 180 deg turn to the right & then a 180 deg.

turn to the left, like an S shape. Once air is deflected it likes to keep

travelling in that direction. Asking charge air to open out at 360 degrees, as

in a 50mm pipe into the middle of a 90mm flat rectangular tank, causes a

big pressure drop. Another problem is Heat soak, especially when the

throttle body faces across the tappet cover on a north/south engine or at the

rear of an east west layout, making for a long pipe length from the radiator

support panel to the plennum. Why is this a problem? We have measured under

bonnet temps. of over 80° c. & that is not down near the turbo either. On a 26°

c. day, the average charge air temp. out of our front mounts is 30° c. & this

low temp. makes the charge very susceptible too heat soak from the high under

bonnet temp.& naturally, the longer the pipe, the higher the rate of heat

absorption. In these cases, even though we work in alloy predominately, or

stainless, I recommend to do the pipe work in mild steel mandrel bends & have it

HPC (or similar) thermal coated, it is worth the extra time & could be cheaper.

Worst case scenario we have measured between the intercooler outlet & the

plennum inlet, is 21° c. (a 25° day) on a Commodore VL with the pipe behind the

radiator, with a guy in Cairns telling me he measured 26° on his Skyline R32

GTST

When it comes time

to by couplers, if at all possible, pay the extra money, buy the proper high

temp. silicon ones (they look good), fit them & forget them, after you retension

the clamp a week later, they do shrink under the clamp compression. I know hump

hoses cause a little pressure drop, but that can be better than cracking pipes

through not having enough give in the system. If there is only a short distance

for the pipe, & it is between a fixed point (intercooler etc.) & the engine, use

one or two humps too allow for engine movement.

Clamps are important

in both sealing & longtivety of the couplers.

Intercooler Maintenance

This is the worst picture since 1997 of one of our

customers horror story. |

Enough too make you sick !! |

Japan really must have terrible air. The black buildup

actually corrodes into the alloy & must be cleaned.

|

This is how it should be. Back to near new efficiency,

& looks the part.

|

An intercooler that has been

in service for a couple of years (longer in rural areas), will

definitely provide more cooling if it is cleaned properly. That is,

soaked in a degreaser bath to remove the interior oil film that has

accumulated (which may be ever so thin with a new turbo), then power

flushed with water. The exterior fins should sprayed with a proper

aluminium etching cleaner to remove the surface oxidation & road grime

that will have formed. Both the oil film & oxidation/grime buildup

provide insulating coatings that inhibit the transference of charge air

heat to the ambient air.

If not sure of the proper procedure

& products to use, we strongly recommend having this done by a professional

business in our field. Please see the two pictures above left, which is a 9

month old intercooler that was removed off the car for another reason, & the

owner decided to do the right thing & clean it to be sure of maximum

performance. He rang us & I told him we use a Degreaser, Kero & Phenol solution

in our bath. He already had some degreaser at home, so bought some kero, mixed

them, blocked off one end & poured the mix in to let it soak. It started to get

warm after a short while, then bubble gently & get hotter. By the time he

realized it was going awfully wrong & tipped it out, this was the result. It was

late Friday afternoon when he rang, both of us were in a hurry, I

didn't say & he didn't ask about different sort of degreasers and he

didn't read the label which said 'not for aluminium'. It was a water

degreaser he had & mixed with the kero. The caustic base of the degreaser

attacked the alloy & rendered the core completely useless, a new core being the

only alternative - expensive mistake for both of us, as we helped him out with

the cost. I rang a few industrial chemists & the answer was the same from them

all - over the left shoulder. For internal cleaning, only

use a petroleum based degreaser, which we mix with Kero & phenol.

Specific acid cleaners must be used on the external cooling fins as the average

thickness is only 0.08mm - that's paper thin. Any bent over fins should be

straightened before the cleaning process, so the fin is cleaned properly &

full air flow is allowed through the core.

Check all the mounting brackets,

both on the cooler & car for any signs of cracks. If you have to undo or loosen

any bolts, take notice that the brackets don't 'spring' or have tension on them.

If so, fix the problem so the bolts go straight in easy. This will stop any

stress cracks forming or spreading.

Check all the hoses for any signs of

deteriation, especially next to the clamps & in the centre of any convolutions

if the hose has them. These are by far the two most common problem areas. When

buying hoses, do your car a favour & pay the extra for proper high temp silicon

hose. Buy it once, fit it once, & forget it (after checking clamp tension after

a week). Remember that hoses shrink under compression of the clamp, so when

reassembling, make sure that the clamp not only goes back in the exact same

position but also around the same way, as the tabs under the worm drive

mechanism are asymmetrical & could allow charge air too escape. Same with

radiator hoses too. When buying clamps, always make sure the band part has a

rolled edge on both sides, this stops cutting the hose with time, as they must

be very tight if boost is over 10 psi. If over 20 psi. I recommend using the

T-bolt clamp.

One really top, time saving trick I

was given by Matt @ Chiptorque (Nerang) is to plumb an air line set at a couple

psi into the inlet system & listen or feel for the leak if you're having trouble

tracking it down or have doubts. A small leak is next to impossible to diagnose

with the engine running sometimes.

Repairability

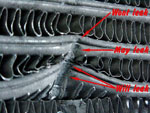

This oe Nissan GTR core does not leak. Because

there are no sharp creases in the damage, it will probably give

several years service. |

This Skyline GTST is going for scrap. Tubes

probably don't leak now, but tubes torn out of header plate &

tank holed.

|

Close up of damage. If "will leak" tubes aren't

leaking now, they soon will with hot/cool & pressure cycling

|

|

When considering tube

construction, one thing to remember is the strength & repair ability of

the cores. The weakest core by a very big margin is the plate tube & fin

core. We get allot of these through our workshop (including oil coolers

of the same construction), but they are relative easy to repair as they

mostly crack in the centre of the end tank concertina joins. If

the crack is in the centre of the "tank" end, then it is a throw away.

They have to be hydrogen brazed as the heat from TIG welding is too

concentrated, usually resulting in a weep at one/both ends of the welds.

Bar & plate cores are weaker than tube & fin. The worry is that

Garrett paperwork says that it is acceptable to have leaks in the core,

as long as it doesn't exceed 4 psi drop from 30 psi in 15 secs !!!

We may have had a leak in a tube & fin core over the years, but no

new intercooler has ever left our shop with a weep, let alone leak.

Bar & plate cores are very difficult to repair leaks anywhere on them

because of the vastly differing thickness components , but tube & fin

are only hard when the leak is in towards the centre of the core by more

than 15mm.. The wall thickness of an Adrad core is 1.3mm

front/rear face & 0.7mm for rest of tube and K&J is 1.0mm front/ rear

curve & 0.4mm sides of tube. Any competent aluminium welder will be able

to weld damage to the tubes, but burning the fins away will sort out

their talent ! This advice is from

our workshop, that is one of the few set up too repair properly as well

as fabricate new assemblies - in fact there is not another shop in

Australia,set up anywhere near as comprehensive as us, for repairs !

Import or 'Grey' Intercoolers

These are a much preferred

option to the Truck intercoolers, talked about below, in fact, some very

good units can

be bought for a value price. If the unit has not been stored properly

after it was removed from the vehicle (& this means in the wrecking yard

in Japan, loading onto & in the container coming over here & storage

over here), then it may in fact, cost you money &/or performance. They

have been brought in to us for cleaning with a line of whitish powder

1/4 to 1/2 way up the core internally, from where they have been laying

in the salt water coming over. Don't touch them. Sometimes, they have

looked real good, but after we have soaked them in the bath & while

power flushing, the amount of pebbles, dirt, & the odd self taping screw

that comes out, is a real worry. Firstly, too us that we have got all

the rubbish out, & secondly, that anybody buying one & fitting it

straight up, has been lucky & it is clean, or else whatever is in there,

will finish up in the engine sooner than later. Paranoid? no, seen

it happen too often.

If an import intercooler is

for you, then look for a unit off a car that has at least 50% more power

than your engine, as oe. intercoolers are sized by accountants, not

engineers. Even if the engineers do get the final say, I'm sure they

know how much some of you guy's will turn up the boost & so have a small

intercooler to try & "choke" your gains !

Truck Intercooler Cores

There are differences

between a 'truck intercooler' and an intercooler fitted into a

performance car application. However, 'truck intercoolers' is a

broad term and does not sufficiently categorise the product. Just

like other types of products, truck intercoolers come in different

configurations - both bar and plate and tube and fin design. I

have not seen a plate tube & fin core in a truck, they would be too

weak. However, due to their specialised application, truck

intercoolers have a noticeably courser internal fin &/or external fin

pitch (depending on whether tube and fin or bar and plate), than their

cousins fitted into normal performance car applications. This means that

although a new truck core can be used in performance applications, the

core surface area/volume must be larger in proportion to that of a

standard 'performance core', & then it will give good temperature drop,

but it will be at the cost of a medium/ high "static" pressure drop &

higher radiator water temperatures.

A truck intercooler core is

nearly always larger because even though the engines are slow revving,

they have a large swept capacity requiring a high cfm. intake charge,

also there average road speed is much slower & the engine is under load

most of the time. Because of the slower road speed, thinner cores per

area and with less fpi., are used to keep the air speed onto the water

radiator as high as possible. 37mm thick is used by truck manufacturers

in there lower powered applications, but you hardly ever see them in a

performance application. Trucks also have a large frontal area, giving

more room for the intercooler/radiator.

We cleaned out a Volvo truck

intercooler (it had plastic tanks) & during the job, discovered that it

had no internal fining, turbulators, nothing, inside the charge air

tubes at all. When the customer came to pick it up, I asked him how it

going on his car (Cordia), & he said brilliant ! He had never measured

the temperature drop, & I guess he drove pretty easy, so it may do a

reasonable job, but put it on a Commodore & it would be hopeless.

The larger volume of a truck

intercooler has three main drawbacks:-

1) Higher 'static' pressure drop

2) Increased 'turbo lag'

3) Higher engine water/under bonnet temperatures - in front mount

applications, as the large truck intercooler blocks more of the air flow

through to the radiator.

Therefore, if money is a

major issue than new truck cores in a performance car are a viable

BUDGET

alternative, especially if tanks can be made & fitted at "mates rates"!

Used Truck Intercooler Cores

It is my opinion that used

truck intercooler cores should not be used in a performance car.

Using a used truck intercooler core is a huge gamble, are you prepared

to risk the welfare of your engine because of a cheap intercooler.

Why put a $100 core in front of a $2000+ engine? It also is a slow job

to do properly, as compressed air has to be blown through the tubes,

from the opposite end to which you are working on.

Most truck intercooler cores

can fit into a performance car application, but they nearly always have

to be modified. During this modification process, whether it be

when the old tanks are being cut off, or when the core is being cut down

in preparation for welding tanks on, or when the tanks/core is being cut

down, swarf and fillings can get lodged in the core, some of which can

be up to 600mm in length and can be imposable to blow or clean out.

The result is that they dislodge days or weeks later, after working

their way through the intercooler tubes and intake piping and end up

passing straight into the engine. I'm sure you can imagine the

result of that !? Another point is that bar & plate and finned tube

cores are much, much harder to clean any solid particles out of as they

get trapped in the fins & have to "travel" through the length of the

tube, interestingly, the exact same reason why per sq. cm., these cores

dissipate heat better, but at a higher "static" pressure drop.

Remember that a used truck

core is for sale for a reason. If you buy one, hope that the truck was

hit up the arse, because if it was hit around the cab, then the core was

more than likely damaged or twisted to some extent. If the damaged

section was cut off, your core will still have some stress & 'set' in it

& even if not leaking when purchased, the heat & cutting when modifying

it to fit, may release the stress, resulting in leaks in the header

plate/ tube joints when finished. We do not do this work anymore for

this reason, it happens far too often !

Picture of core in test tank.

Used truck cores in a

performance car are a stupid, desperate alternative, & if you haven't

guessed, a pet hate of mine. Use them in your smoky turboed A12 powered

rusty 120Y, but please not in a performance car. I'd much rather see you

buy from an opposition shop !!

Last words.

Intercooling a forced

induction intake charge is a compromise. We direct all our energies &

R&D., at minimising the negative compromises & maximising the positive

compromises!

A 20% gain in air flow through

a component, does not give a 20% increase in power - I wish it did ! It

might only result in a 0.5% (or 5%) gain in power - it all depends on

the application.

If you have read this far, I

thank you kindly, because it has taken me allot of work. I've tried to

be as honest & unbiased as I could, so I really hope you found it

both worthwhile & especially educational. Spend your money

wisely, & you'll always be ahead.

Short Glossary

(for a our full edition

click here)

* "Static" pressure drop -

The measurement of the drop in pressure of the air travelling through

the core, friction or 'parasitic drag' measured on a flow bench (of

capable capacity) at ambient temperature.

* "Dynamic" pressure drop -

The measurement of the drop in pressure of the air travelling through

the core, friction orO 'parasitic' drag plus the drop in pressure caused

by the cooling of the intake charge (closer molecular structure of the

particles resulting in a denser, smaller volume exiting) due to the

mechanical design of the intercooler, or in more engineering

terminology, thermal matrix heat exchanger!

|