|

AIR / WATER

Intercoolers

|

I

don't know how I can stress enough how unique

& accurate our in house computer programme is for

sizing air-water intercoolers, but please take the

time to look @ Heath Lawson's

PDF

file & Craig Munro's

PDF file, & then the results acheived. |

I believe this

is the biggest, most

efficient automotive air/water system fabricated to this

date. It is definitely the only one that was computer modelled

before starting, & so far, has performed within the parameters

as given to the tuning shop -- our 'in house' programme truly is

that good !!

It has it's

own page so click on any of the 3 pics to open.

These are our first

cores with our brand new tube. There is a bunch of heat

dissipation here !

There are 52

pictures & 18 graphs on this page.

|

|

|

| These

are the 4 different cores we have tried in air/water

intercooling to arrive at our own new design. From

the left - Spearco bar/plate, K&J intercooler, K&J

oil cooler, modified dimple radiator, & our new

core. |

This is

a close up of the modified dimple wall radiator

cores we used in our 3rd generation a/w intercoolers

on top of our new tube. Very good but really had to

have heaps of water forced through them - not enough

water to the charge air ratio& to thin wall

thickness. |

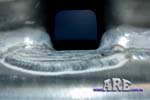

This is

a close up of a spearco bar/plate on top of our new

tube/fin a/w core. Note the BIG difference in

material thickness & surface area for heat soak - in

yellow. The b/p core was similar (but better) than

our mod. radiator cores. The coarse fin pitch on our

core was made for a reason. |

We started

testing our first generation air/water intercoolers in early

2000 -

project rodeo

- after 12 months of research. Up until then, AVO was the only

company commercially manufacturing air/water units in Australia.

Our units were made with modified tube/fin intercooler cores, &

even though they did a good job, we realized that they had too

large a water tube to charge air window ratio.

Our second generation 'cooler

came on line in '01, made with a modified radiator core -

project Hi Lux

- & while it was an improvement in most circumstances, testing

in a number of vehicles proved that we had gone too far the

other way, with not enough water for the charge air ratio. We

had to oversize the pump to get good cooling.

AGAINST -

Complexity & Cost.

You need a second radiator, water pump & preferably some form of

pump speed control, 2 speeds will do the trick. They are much

harder to size, this is why we have pumped hundreds of hours

into data logging & creating a sizing spreadsheet programme.

Under the same circumstances, drive in/out will be approx. 20 to

60% dearer.

It

also became apparent after a couple of years testing that I had

to down grade my initial cooling estimates of air/water

intercooling, which is a disappointment, but necessary. I

thought that I could design a system that at speed, would cool

the charge air within 4ºc of a front mount - both systems being

equally engineered. It appears 8 to 12 ºc is a real world

figure. Please put this into perspective. A 'front mount' car -

Skyline GTR, 180 - 200 Sx, Supra etc. will give results on a

25ºc day of 31 - 36ºc into the plennum. An air/water setup will

give 42 - 48ºc under the same circumstances, but a 'non

front mount' car - Skyline GTS-t, VL Commodore, Subaru - any car

that doesn't have a front facing throttle body towards the

radiator support - will give similar temps. due to

heat soak in the long return pipe from under bonnet heat -

approx 70 + ºc, even though the charge air in both air/air

setups, exits the 'cooler at 31 - 36ºc.

FOR --

Now, the above paragraph is the only time a front mount will out

perform an air/water if both are set up properly - at speed .

Stop/start, drag racing, towing, 4 x 4 offroad etc. all gain

from air/water. The charge air temps. into the engine are also

much more stable with logging showing a spread of 35

to 40ºc around town & 35 to 50ºc laden in soft sand, 2nd gear

low range, whereas, front mounts have logged 30 to 65ºc around

town & 30 to 95ºc in sand. This is with turbo outlet temps of

140ºc as for a top mount, 38ºc c to 116ºc have been

recorded ! When you have your foot right into it at slower

speeds is when detonation is most likely to happen, air/air

intercooling is performing at it's worst efficiency. A very big

fan under a top mount will make a fair difference & to a lesser

extent, behind a front mount, but none can get near the fact

that water 'holds' heat 37 times better than air & a thin

radiator at the front of a vehicle cools better than a thick

intercooler (air flow), & also has much less effect on the

volume of air flow too the engine radiator - very important with

some vehicles - eg. 70 series Landcruisers. Take a Toyota MR2 &

they have no opposition really. Also, this small heat spread

allows safer 'set it on kill' tuneups, if that's your need. It

also in a small way, helps engine component longetivity with

head gasket, top piston rings & valve seats benefiting most.

Another big plus is is with the length of the inlet track. Some

cars have a bunch of pipes to get from the turbo to the front &

then back to the throttle body - Subaru WRX springs to mind.

It's not so much turbo lag as, filling the volume lag.

Sometimes big holes have to be cut in the inner panels for these

pipes, so when you go to sell the car, you have to leave the

intercooler on as the holes give it away. Two 25mm hoses can be

routed to the front so when they are removed, no evidence exits

of a performance enhancement being fitted - higher trade in ?, &

your air/water setup could be sold for maybe a 50 % return.

Add an engineered ( or even a simple ice bucket) ice water

chiller & the results of air/water intercooling over air/air are

undeniable. 1 to 1.25 % power increase for every 10 deg.

Farenheight decrease, is the possible horsepower gains - note

the imperial measurements. If you have an all out engine

combination, this can give you the winning edge - safely !

If you are making 600 hp with 150 deg f charge air temps & an

air/water setup reduces this to 70 deg. f. - then a power gain

of 60 hp is possible. I buy most the turbo magazines

from around the world every month & have done for 6 years. Over

the past 2 years I notice that 85% of featured new drag cars are

fitted with air/water intercooling now. It is the only legal way

of getting the charge air temperature down near or below ambient

air temperature, running petrol. Methanol as a fuel can get

reasonably close, & as an injected additive does a good job, but

watch the corrosion. Water sprays can be banned at Dragstrips &

some Dyno competitions, although fine for the street.

Data

Logged Air-Water Graphs

The following

graphs are from our new Motor Sports Electronics ( 02-4648 0030,

or

www.msedata.com.au

) Data Logger. These are CAMS mandatory Logger

for Nations Cup - GTP race cars, so it is good. With more & more

of our customers running high end ECU's with accurate logging &

relaying this data back to us, & the results from our dual

digital thermometer testing differing from allot of earlier data

supplied by our customers & some of our logging, made me realize

we were not accurate enough with our data collection. That's

changed. We can now log eight analogue & four digital

channnels,100 times per second for four minutes ( or 25

times per second for16 mins), & some of the results really do

differ.

Our problem is that with this new accuracy, publishing our test

results here will make our

product look inferior too some

other resellers & internet users, who do limited or no testing,

instead, advertising claims/results that are impressive but

unsubstantiated, &, if tested, are way wrong. Yeh ,

' I've got a bee under my bonnet ', but that's life. I'd much

rather miss a sale or sales, and be accurate & honest with those

who are thinkers & choose to deal with us because they know

exactly what they're getting !

Please do the following as a favour to me for having the guts to

lay it out -- since '03 I've had to revise most of our claims, -

up !

-

Reference

all temps off the Ambient air temp. This is the only

way to compare different tests - ours or others, as it

slides all of the temps up or down the graph . Winter

testing makes cooling look so much better, but summer temps

are what hurt performance & can actually destroy engines

much easier.

-

If comparisons are with any data that does not state an

ambient temperature, don't waste your time.

-

Please give some thought to the reasons our data may differ

to other data, obviously & especially, if we're looking

bad. Most commercial sensors suffer from heat soak from

there housing body, we probe just the wire into the air flow

to get these results.

-

Temperatures are not

indicative of power outputs. A large capacity engine with a

big efficient turbo & lazy tune, can have an outlet

temperature of up to100°c

less of that of a

small engine/turbo combo. tuned to 'the edge'.

-

We do not log speed or engine revs. Boost is logged where

possible.

-

Check the rate of rise (& fall) of the turbo outlet charge

air, some street combos can record a rise of 100ºc in 0.08

seconds ! & we wonder why we see fretting of surfaces &

exhaust manifold cracking etc. Expansion & to a lesser

point, contraction of some materials is really active,

especially in circuit track work etc.

-

Unless noted otherwise, these tests are carried out

accelerating from a standing start up both sides of a large

hill. The graph rapidly rises on acceleration & then slowly

increases due to boost &/or heat soak, until the top of the

hill is reached. It drops & tapers off coasting & braking

down the other side. Sometimes a spike shows the u-turn &

then the process is repeated back the other side. Backing

off for a car in front & gear changes in a manual are

obvious

-

The vertical grey line is the reference line of the loggers

figures shown in the bottom data bar.

-

' Efficiency' is calculated with the

following formula =

Turbo Outlet -

Manifold Inlet

Turbo Outlet - Ambient Temp.

Customers cars Logs for comparison.

|

|

|

|

|

# Tony's

TD5 Defender. Just been chipped by MR Autos.,

otherwise as oe. Fifth gear was reached up the 1st

hill & 4th on the return-shown as spikes. Please

note this is oe. front mount air-air

intercooling, shown for comparison. More

efficient at speed only.

#

please read note

below |

Tony

Patrol 3.0L let us log his car with a leaking oe top

mount intercooler. It allows us too show what a

pressure drop will do.

Click here to see full details. 137ºc out of

turbo, 85ºc into the engine on a 32ºc day, worst

scenario. |

This is same car after we fitted our new upgrade

73mm core. No

leaks. 119ºc out of turbo, 68ºc into engine on a

30ºc day, worse case again - a bit more efficient,

but much more consistent cooling. Note also how

turbo temp dropped. Factory top

mounts are inefficient - some are shockers ! |

This is

Toy. L. Cruiser 100 series which has been fitted

with a non intercooled DTS kit. We are fitting our

air/water ic kit very soon. This vehicle carries

allot of weight. The turbo seems very efficient with

only 112ºc under a period of full load, on a 32ºc |

| oe IC.

efficiency = 71.8% |

oe IC.

efficiency = 49.5% |

are IC.

efficiency = 57.3% |

pipe.

efficiency = 1.2% |

| #

This is the factory front

mount intercooler, vehicle been chipped & tuned for

Australian conditions which helps a little with

cooler temps., & the 71.8% efficiency is why we do

not do any upgrades for this vehicle - a smallish

gain will be expensive. |

Our Air-Water Tube

Development story

This new tube

extrusion is the result of five years of research &

development carried out on our Air / Water intercoolers. The

first cores used modified intercooler tubes, but flowed too much

water for the charge air flow. For the second series we used

modified water cores, but these were the exact opposite, with

very high volume & pressure, pumps needed to achieve efficiency.

The most efficient a/w intercoolers we had made were with the

K&J oil cooler tubes, but water flow was still sensitive & the

tube area too large in relation to the fin area. Over these four

years, I was extremely lucky to have the input of an Engineer

who was contracted to the Australian engineering arm of

Caterpillar, in both Load Stress & Hydraulic Design. Soooo

(?), what's much more important is that Danny is a 'petrol head

enthusiast' who already knew the advantages of air/water

intercooling & so helped me with great enthusiasm with his deep

insight ! The ARE Sizing Spreadsheets were originally created (&

are still being fine tuned) by Danny with some input from me, to

short cut development time & create a superior product. Now, I

find that they keep me focused on the strength & weaknesses of

this system & really do make sure we can supply the very best

product

possible. Our design criteria was maximum heat transfer with

minimum pressure drop. Juggling the smallest tube volume (for

fluid speed) to the largest internal surface area ( for wall

contact) ratio parameters, is the secret.

Last year

when I first discussed with the Engineers @ Adrad where we were

at with our new extruded tube design & needing a factory too

manufacture the cores, it very quickly became apparent that the

costs were out of ARE's reach - or maybe I wasn't prepared to go

that far into debt! It now became a joint effort, with Adrad

both bankrolling & manufacturing the cores with our tube design.

They went to their supplier, Capral, to make the die & supply

extrusions. Not good. We were seriously messed with in the die

manufacture. Three separate times we had to make changes to the

design to enable the die to be made, being agonizingly slow

getting back to Adrad. Each time the Adrad drawing dept. had to

draw up one or several alternatives which ARE then ran through

our own computer spreadsheet programme, coming up with the most

efficient alternative. When we thought we had it right, Capral

said that they still couldn't make the die & wanted more

changes. Up until now we had been able to computer model the

changes for minimal losses, but now we were looking down the

barrel of some real compromises. During discussions, Capral

tried to outsource the die manufacture overseas, with a company

in Germany that they use, saying they can make the it. However,

one very small change had to be made, or the cost was many

thousands of dollars extra . Computer modelling showed that it

was a small sacrifice, nowhere near justifying the cost.

My point? This is a very complicated & the best possible tube &

fin design that is realistically available in the market place

today, & hopefully for a fair while time to come.

One of our real

advantages is complete versatility. We can have cores

manufactured for us with any intake window width of 100mm to

1200mm with a height of 50mm to 1200mm in tube multiples of 11

or 12mm. Core depth starting at 37mm & going through to a length

of - well 10 or more metres if the application

demanded & the customer could afford it. Fin pitch can be

anything from 5 fpi to 20 fpi. or in a fluid to fluid cooling

situation, no fins at all. Get the picture, we can cool an

engine - maybe I should say machine - from a 6kw, 50cc -

to a 10,000 kw. plus, 30 litre plus whatever, under the right

circumstances. Please don't Email me & waste both our times with

ridicules scenerios, I'm trying too show how versatile our

product can be - we are into performance automotive applications

- & obviously applications are limited by charge temperature -

400 deg. c., charge speed, sheer size &/or weight, cooling fluid

volumes & reserves, & at least 100 other parameters.

Heath Lawson - GU

4.2L td Patrol

t

|

07/03 Heath

does some heavy duty 4x4 competition & came to us to

see if we could drop his inlet temps down as he was

looking for more power & was concerned about his

inlet temps at full throttle/low range, even with an

aftermarket top mount air-air fitted.

This is the top of the

air water we built for him

This is the bottom of

the unit. Note that we fitted 8 npt bosses for

temperature sensors - we like to see our products

being comprehensively tested. We used 2 of our Hot

Chilli tanks for the charge air. This unit was made

before we received our new tube, so we could now

build an even more efficient unit !

These are the

recovery (foreground) & distribution tanks we made.

These add nothing to the actual cooling rate, but

are to make sure that the system is always

completely full (check

this) compared to (this)

& there is enough water capacity in the system. If

there is not enough water capacity, a steam pocket

will develop in the 'cooler & it's useless !

Remember the charge air is always over 100ºc under

high load, so it will boil the coolant.

Under bonnet pics. of

the system fitted. No, the hose sizes aren't

overkill. We have developed a computer programme

over the last three years that gives us just about

complete data for this system before we start

fabricating - & we're backing up the theory with

practical data logging - most of the time -

occasionally there's a hic up.

This is the

6

page PDF file from ARE's own computer programme for

sizing inter -coolers. Note on the first page that

our intercooler removes 25.2kw of heat out of the

charge air. A small household air conditioner is

approx. 1.6kw & a unit to do a lounge, dining &

kitchen is 8kw - so our little intercooler really

does do a big job, & this is why we put so much

effort into them. There is allot of hidden

information still!

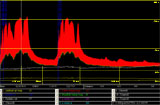

This is a log from

our first Datalogger. The red vertical line (@ 10

secs.) is the reference point for the temp figures

below. The Ambient temp. was not logged, but was

26ºc. The charge air temp. out of the turbo is 138ºc

with the temp out of the intercooler being 52ºc. The

39ºc is a spot under the bonnet that we wanted to

log for future reference. Intercooler

efficiency is 76.8% & resulted in the power gain on

the chart below.

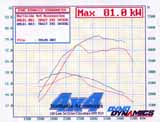

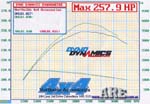

This is his dyno

sheet from Northside 4x4 (07- 5495 5549) of before &

after. It's also a perfect example of why I don't

take much notice of these dyno graphs - unless they

are accompanied by what I call the 'boiler room' -

the two sheets shown below. Notice how at 2450 rpm

the two lines meet with a big spike in the before

graph. Wonder why? without the boiler room sheet,

we'd never know, but we only have a look at the two

sheets too see why. 81.0kw is 108.6hp.

These figures are at the rear wheels with 36" mud

tyres, so the flywheel output rating is allot higher

- know I'm not conversant with the conversion

formula.

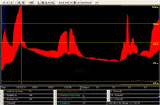

In this 'before'

graph, the boost starts jumping from 9.4lb @ 1800rpm

up to16lb @ 2340 rpm & then back to 9.5lb @ 2550rpm

slowly rising to 11.3lb @ 3600rpm. I

don't know what caused this spike, but the afr. (air

fuel ratio) & ex. temps didn't mind much so it

wouldn't do any damage to the engine.

Now in

this 'after' graph, boost is 10.6lb @ 1800rpm

& stays around 12.4lb, thru to 2500rpm & then slowly

tapers down to 11.2lb @ 3500. It is so much more

stable & on average, apart from the spike, abit over

1 lb higher due to less pressure drop in our core.

The exhaust temps. are also much lower but it was a

little cooler day. A cooler

intake charge will give a little cooler

exhaust gas temps.

At 1700rpm our a-w intercoolers output went from 43

up to 51rwkw., or a gain of 8kw more. This

18.6% increase over top mount, & looks

after the engine better too boot !

At 2850 rpm our rwkw output went from 71kw up to

82rwkw, or an increase of 12. This is a

15.5% increase over top mount. Not bad

for replacing a competitors air - air intercooler

with one of ARE's air-water units. The

increase out in the bush or sand, will actually be

more, because the dyno fan blows heaps more air over

the bonnet than at 10 kph vehicle speed, BUT at this

speed our front radiator will be getting added air

flow from the engine fan, and water can hold heat 36

times better than air.

This is Heaths

signed vindication of the gain from fitting our

intercooler over the aftermarket one he already had.

Gains from 25% up, are seen with intercooling a non

intercooled turbo diesel. Be very wary of the

boost you run if you turbo a naturally aspirated

diesel & don't intercool it ! |

Update on Heaths diesel Patrol. -- 258rwhp.-

(198kw)

This

is 193kw @ rear

36" tyres! Wow ! This

is 193kw @ rear

36" tyres! Wow !

|

This dyno graph is from the May

Labour Day competition @ the 3 day Landcruiser Park

bash. If this hasn't caught

your attention, then you must be a petrol head with

no knowledge of diesel engines. To put it into

perspective, with the same big chunky 36" tyres &

the same diff., he has gone from 75.3kw. with the

top mount air-air, to 81.0kw ( 7.6%increase) with

our air-water, to 193kw (138%increase) with our

prototype air-water intercooler-plennum unit !!!

Obviously, there is allot more than our intercooler

involved here. He went to a tubular exhaust, ball

bearing Garrett turbo, tidied inlet ports & a very

special big $$$ fuel pump. All the work was

performed by Heath & Ian with product from

businesses in south east Qld.

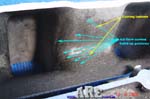

These three pics are what I used

to convince the guys to go with an untried idea I've

had for years, & spend much more than they wanted

too. I had shown them the six pages of our computer

modelling programme with a few different scenarios,

& they knew that was very accurate from past

experience, BUT, there was two stumbling blocks. The

plennum was untried & I'm not that big into diesels

so didn't give any guarantees, & Ian said that he

could do a Chev V8 conversion for similar money -

valid. Heath pointed out that while a V8 could have

more power, it would never have the low end Grunt &

engine breaking of these diesels. I'd given them a

bloody good price as they were the 'guinea pigs',&

it would be two at the same time, so it was crunch

time. I clearly remember the guys talking it over

out at their car for over an hour, before coming in

& laying a deposit down.

The carbon build up is a give away to the poor

factory design when the boost is raised. The blacker

the area, the slower the air speed &/or turbulence,

meaning those cylinders are not getting the same

amount of air. Three & four are clearly the lean

cylinders & will burn the pistons up early (or at

least dramatically shorten head gasket - valve -

ring life at best) at the tune levels these guys

wanted to go to. We also considered welding the

single entrie & making two entries into the oe log,

which would've been heaps cheaper, but I bet they're

bloody glad we didn't take that shortcut.

It's not the sort of job you get a

mate to do for a couple cartons. There's my thirty

years of air flow bench & 20 years of TIG welding

experience in this. I had to pad weld this part of

the inlet to get a very smooth transition with the

best transition angles. In fact, I picked up a

little flow on the second plennum, so cut the first

one off & did the same mod to it, at no charge. Not

many shops are that conciencious - or maybe I'm a

dickhead?

This is tricky welding, 3mm plate

butted onto 4mm plate of cladded alloy, 4 mm from

0.03mm fins & it has to be a full penetration

weld as it has the full weight of the cooling matrix

hanging off it.

Trial fit up during fabrication to

make sure everything lined up. The engine is

swallowing over 900 cfm now, & with the chunky tyres

throwing rocks, dirt & dust everywhere, filtering is

paramount. I just can't stress this enough. That's

why we fitted such a big K&N pod filter & our own

easily replaceable foam pre filter that slides in

the mesh near the entry.In a sense the inlet track

is 20mm long as that's the total of length between

the turbo outlet & tank inlet. How much lag?

Compared to a front mount it's almost unmeasurable.

Even though our plennum is 478% larger than oe., lag

is heaps less than a front mount instal

850rpm,

2500rpm,

4500rpm

- front mount & pipeing -

0.691 sec

0.235sec

0.131sec

- our air water/plennum assy.-

0.499 sec 0.169

sec

0.094sec

the above figures are from are computer modelling

Lag programme. They are how long it takes a molecule

of charge air to travel from the compressor housing

outlet to the valve head, at the rev. stated & if

the pipes are straight. There are far too many

variables to be able to calculate accelerating lag

as you can see it is exponentially quicker as revs

rise.

This is the end result on Heaths

truck. He kept the same radiator( which will

struggle on a long straight on a hot day), & of

course, the Davies Craig EWP will handle the flow

easily.

Apart from cost, the only other problem could be

longetivity, with so much weight swinging off the

top of a vibrating engine & then being pounded be

such rough use these guys throw their trucks at! We

have done everything possible with both materials

used & fabrication skill & tricks for the longest

life possible. The air speed in the short 63mm pipe

connecting the compressor housing to the the ic.

inlet tank is 254kph! We're now pulling 63kw (3583

BTU/m)of heat out of the intake charge, allowing

their other engine mods. to achieve the impressive

power output. They're good turbo petrol engine

specifications, but then I'd love to see this engine

in a 1400 kg VL Commodore beside allot of imports at

the lights! It would have similar power to a HSV 300

kw Monaro, less weight, & don't even think of how

much more torque !! What a burn out weapon - mega

grunt at any revs.

The air speed in the 4" snorkel is

92kph! so you can see why I talked them into such an

elaborate air box - it's necessary at this level

believe me. |

Rod Brennen - BMW

M5 Supercharged

This is a variation

of our usual air/water intercoolers

|

|

So sad to see this

happen. Rod saw an air/water unit like this on a

USA. internet site, recognized straight away the

advantages for his new blower set up & sussed out

having it fabricated in Sydney. Weeeeeeeeeell, the

results of what he was charged for are shown in the

top two pictures, beside the unit we fabricated for

him. The guy sounded totally confident & competent,

so Rod just went ahead & ordered it. The sad thing

is that the shop took money for this botch up, gave

it to him knowing it leaked. When it's a tricky job,

if you haven't seen someone's work, make sure you do

before committing your money!

It almost looks like

they ladelled the alloy filler on, like a person who

can't solder! One of the worst "professional" jobs

I've ever seen, & it's not as though it's for a low

dollar car either.

The air/water unit we

made was 66mm longer & 8 rows of tubes high instead

of 6 rows, giving 48% more cooling area straight

off. Plus we shaped the inlet to trap 90% of the

charge air instead of approx. 50% of the other.

There is a surprising amount of cooling on offer

here because of the surface area provided by the two

core matrix. Because of the tube length, a fair

water speed through the core is needed. If this was

a tougher engine combo, then we would've routed the

water differently through the cores, approx. 20%

more cooling is available, but because the engine is

a sensible street combo, this unit will remove most

of the heat out of the charge air anyway, so a waste

of our time & his money.

ARE's in house

computer programme gives us the volume & speed of

the charge air, the heat kw. that needs to be pulled

out of this air, how long it's in the core for (only

milliseconds in this case), speed of the water

through the core, how long it's in the core & how

many Kw's heat the water can transport out. Then

it's a matter of adjusting the water flow, sizing &

configuring the front radiator, sizing the hoses (

that's another programme we have developed) & it

will work pretty bloody good!Actually we're not that

smart - as of the end of '03 our programme has an

accuracy of +/- 6% for most calculations, up to

+/-15% for some & total accuracy for some. By the

end of '04 I want these figures @ 3% & 10%.

The finished unit in

it's place in the air box. |

We built a number of intercoolers like this with modified

radiator cores & while they worked good, found that the water

tubes were too small in relation to the charge air passages.

I really

like owning /doing something that's different to normal,

definitely not because I'm extrovert (I'm actually shy

in a crowd) but because of the challenge & satisfaction

usually associated with the end result. Buying this

truck to replace my Rodeo was the result of a chance

remark during a conversation on another topic. From when

I first heard about it to ownership was only 3 days,

helped of course by the payout chque on my burnt truck,

so it looks like good can come out of bad.

Richard

Larson of Loadsafe Australia (who incidentally are a

company qualified to engineer vehicle modifications

-(07) 3851 1066), bought a body damaged '95 Toyota Surf

3.0 litre automatic through Eureka Trading (07) 3865

1205, & then a 95 HiLux single cabin together with a '95

HiLux extra cab style side back. By welding the

appropriate mounts onto the chassis for the tray, the

vehicle pictured above is the result. Looks different?

The Surf, apart from having a coil sprung rear end, is

shorter in the wheelbase by the same length the extra

cab cabin takes up, what a lucky coincidence. It should

ride really nice when I get rid of the stiff coils &

shocks some Japanese guy had fitted, must've been trying

to get it to handle like a sports car!

Vehicle

Specifications

1995 Toyota

surf chassis with 1995 single cab body & extra cab tray.

AU Falcon blue & Pearl Silver.

Engine is a

1KZ-TE 3.0 litre 4 cyl. turbo diesel -non intercooled -

electronic controlled injection.

Transmittion

is 4 speed Automatic with rear LSD & electronic locking

front hubs.

Wheels &

Tyres are 16' x 7'' alloy with 265/75 x 16 Dunlop

tyres.

So Far

I've

added a vacuum/boost gauge to read off the intake

manifold & a probe in the inlet pipe out of the turbo to

give me the inlet charge temp. The boost max's. just

under 11 lb (10.8 lb) & is a little slow to come on,

especially from a standing start. A high stall converter

would help that initial jump off the line, can you

imagine ringing up the Converter Shop & ordering a high

stall, like all of 1200 RPM., Jeff would probably hang

up! Once a couple of meters have been traveled,

acceleration is surprisingly brisk - for a diesel,

remember the ute is lighter than a surf waggon. The

temp. gauge mirrors the boost gauge in that more boost

used, the higher the temp. Normal cruising throttle is

approx. 3lb. boost @ 66ºc.

Full throttle up hill is 11.4 lb @ 102ºc.

106.8ºc

is the hottest I have seen, that was yesterday morning

with most of our trade display in the back. This turbo

is nowhere near as efficient as the ball bearing Garrett

fitted to the Rodeo, as @ 10lb boost, 78ºc

was the hottest I ever saw. The other temp of concern is

average 50ºc.

min. sitting idling at traffic lights, - heat soak?

Plan of

Attack

First on the

agenda is to see what can be done with the computer. Not

too many mods. will be if the mixtures cannot be altered

as needed. Next of course, will be adapting the 4

intercoolers already made, to suit this engine, then

onto the Dyno. for power readings & temperature drops.

After this, it's unchartered waters as I know my way

around Hotrodding petrol engines but buggerall of

diesels. Present thoughts are tubular exhaust manifold &

hopefully a ball bearing turbo with a big exhaust to the

rear, 20psi boost, flow the head & tidy up what's

needed, a very small cam grind, an adjustable cam gear,

new intake with plennum chamber & still retain the

throttle body. These will be done as time & resources

allow, but my aim is 150 - 160 kw at the flywheel ! I

would love to hear from anyone who can give me solid

information/leads on reworking high speed diesels for

more power.

20 / 05 /

01

Up the

beach today revealed how much the load on an engine can

vary, I found a natural dyno for 4WD vehicles.

Travelling up in the soft sand in high range loaded the

engine to the tune of 11.7lb boost @ an immediate temp.

of 136ºc

& after a second so, 138 .4 degrees C. was the

temperature of the intake charge. Ambient temperature

was 25.3 degrees. I imagine this will be a similar temp.

to what I will see on the dyno., so there will be some

kw. to pick up here with our air/water intercoolers.

24 / 05 /

00

Bought a

pair of new tyres (one burnt, one singed) & then fitted

the 18' x 9.5" Enkie rims with 285/50 x 18 Pirelli

Scorpion Zero tyres off the Rodeo, onto the HiLux. A

very noticeable difference in the handling sharpness,

wet traction & ride, with all being much better. These

tyres are brilliant in all aspects except cost & beach

driving, as they don't bag as much as a high profile

tyre, guessing at having 10% less drive in soft sand -

most noticeable when accelerating from a standstill (60%

less - it feels like water skiing, a hell of a drag

until it pops up onto the top of the sand). One

important thing is that they are load weight & speed

legal, whereas high performance car tyres are not load

weight legal, this also applies to mini trucks, which

can now run legal big diameter low profile rubber for

the first time!

During

2001

We have been

so busy I haven't had the time to update this, but let

me tell you, it is one nice 4x4 to drive now!

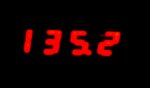

How good is it, well

That's

16.82 secs @ 135.2 kph That's

16.82 secs @ 135.2 kph

on

our GTek meter recorded 02/01. It was run on the

same quarter mile piece of road I always use & back up

the fact that it embarrasses allot of cars off the

lights. Very satisfying too shut down a 'rice' car,

usually when the young guys just look in disbelief &

shake their head. It is just so quick in the first 100

meters, as long as it doesn't turn the tyres too much.

Of course, I'd never street race (for more than 200 m

anyway), so the real pleasure is fully laden with

camping gear going up the beach in the soft sand, or up

a steep hill - yes ! on

our GTek meter recorded 02/01. It was run on the

same quarter mile piece of road I always use & back up

the fact that it embarrasses allot of cars off the

lights. Very satisfying too shut down a 'rice' car,

usually when the young guys just look in disbelief &

shake their head. It is just so quick in the first 100

meters, as long as it doesn't turn the tyres too much.

Of course, I'd never street race (for more than 200 m

anyway), so the real pleasure is fully laden with

camping gear going up the beach in the soft sand, or up

a steep hill - yes !

January

2004

I've been

very happy with the truck & it's performance to the

point of being so busy, not worrying about any more

modifications. Now, with our new air/water tube

extrusion, I will data log the current unit again, &

then build a new 'cooler & data log it's results.

February 2004 Our NEW HI LUX KIT -

final testing

| |

|

|

|

|

This is the 2 row radiator & DC. EWP. we

supply in our kit. ' pic up

soon. ' |

This is our header tank -recovery tank assy.

needed for water capacity. |

This is the intercooler assembly with the

plennum adapter in the foreground. |

This is the kit of our product Water pump,

radiator and hoses are not shown. |

These are

the pictures of our new air/water intercooler that is

now available as a kit for the late '90 1KZ-TE 3.0L. The

new data log graphs are shown further back this page.

Note the number of test leads for our data logger. We

really do get a complete picture of exactly how every

thing works so we can improve any weaknesses.

We have not

been back on the dyno yet & it is not a priority as the

purpose of our new intercooler tube was a little better

performance over our last version - which really gave a

big power increase, BUT mostly - STRENGTH. It was

very concerning to have a 0.3mm (0.012") tube with water

on one wall & charge air on the other. If they ever met,

trouble, as into the engine it goes! Our new tube is

1.1mm (0.044") wall giving 3.7 times more

strength.

|

Started in 2000

We built

a number of intercoolers like this with modified

intercooler cores & while they worked good, found that

the water tubes were too large in relation to the charge

air passages.

Project

Rodeo is no longer...

Due to a

serious house fire in mid March, I have lost my

wheels & test bench in 20 mins. of hell. Good has

come out of the bad & even though I'm down heaps of

insurance, I've been lucky enough to pick up a truck

that may prove to be an even better set of wheels.

Project HI LUX/SURF !

What

happens when you work on customer's hot streeters

everyday? You build your own...

Ingredients:

Result:

-

A 1992

Holden Rodeo, 2.6 liter standard engine, with a

330hp rated Garrett GT25 ball bearing turbo

(supplied by John Patrick @ Turbo Supplies,

Townsville (07) 4721 5133), and a custom air to

water intercooler.

The

Background

When my wife

and daughter dragged me camping 'up the beach' with them

in their '89 Suzuki Vitara earlier this year, I found it

to be the only way in the last 3 years that I stopped

thinking/working ARE. So, I wanted to come up with

a 4wd that had enough room, to use for camping, and for

work........

The Idea

My wife drives her XG falcon Ute for

pickup/deliveries, which she didn't want sign written,

so I'll give her my Mazda MX6 & buy an early '90's

4wd like a Courier, Triton, or Rodeo, stick a turbo and

intercooler on it, add mags, tires and sign

writing, & then watch the sand fly!!!

The

Result

Mathew at Chiptourque told me that a Rodeo up to mid

92 (I found out 10/92) has room in the computer to burn

a program for boost, hence the cost of an aftermarket

computer is avoided. I might add that he runs this

computer in his 10 sec. / 124 mph. Rodeo engined street

Gemini. I spotted a '92 Rodeo Spacecab advertised in the

Trading Post. After checking it out we purchased

it for just under 12 grand.

The

Intercooler

In my

opinion, too many people dismiss an air/water

intercooler without serious thought to if it would suit

their application better than an air/air unit. I think

two of the best uses are for four wheel drives &

especially drag cars or dyno shootout cars. Below is my

"maximum attack" setup which has involved allot of R&D

time, especially in water flow through the 'cooler &

design of the "ice box". I have installed 14 pressure &

temperature sensors to monitor exactly what happens &

help develop this into an ultimate setup. I already have

2 ideas which should improve the results on

big kw. engines, but some baseline results are needed

first. Below ambient temperatures is the goal, & that

sure as hell is what I'd rather have into my combustion

chamber, than the guy in the lane beside me, or next up

on the rollers. Please note that the last sentence does

not apply to a four wheel drive, but the compactness,

lack of piping to the front of the truck & lack of turbo

lag (especially diesel), sure as hell does.

|

|

|

|

The Components -

what it takes to make an air to water

'cooler? NB. radiator, ice box & pump not

shown |

The engine bay -

intercooler and all. No turbo lag here !! |

The ARE custom

air to water intercooler. Sure going to need

HPC on the exhaust here! |

|

|

|

|

|

A close up of

the front mount of the intercooler,

check out the HPC coating colour and the

speedflow fittings. |

Whether it be a

customer's car or our own shop vehicle, we

take pride in our work, especially our

welding & R&D. |

Prototype "ice

box" nearing completion. This should give

seriously cool water to the intercooler |

|

|

|

|

The

Exhaust

We custom

fabricate intercooling piping, why not create a custom

exhaust? This is the first & last time, back to

Gonzo or Custom Exhaust in the future. Don't even think

of asking, this is not my field.

The

extractors we made ,keep the turbo up out of moisture

|

|

|

|

|

The extractors

we made ,keep the turbo up out of moisture

|

Dump pipe with

separate wastegate pipe. |

Wastegate pipe

is aimed into the low pressure area of the

bend. Shield at bottom right is to keep heat

off intercooler. |

Close up of

welding on pipes

|

The Results

Drove the truck for the

first time this week, without water in the 'cooler, only

a short run. Heat soak temperature in the intercooler &

piping after switch off was even more dramatic than

power gains. 3.5 - 4.0 lb boost was all the oe. computer

could handle, but it's booked in on Chiptorques rollers

15/12 to fix this problem. Third gear has 4lb boost @

2000 rpm & fifth gear has 3.5 lb. boost at 1600 rpm.

It's going to be a bloody "stump puller", all I hope is

that there is still sufficient boost at 5500 - 6000 rpm

redline. Thankfully I made the wastegate linkage

adjustable, as first real stab on the throttle resulted

in big rev, blurred needle to10lb. boost, & a near head

butt into steering wheel with "computer shutdown".

Back to workshop & it's now down to 6lb. max. Even at

3lb. boost the truck feels at least one gear better!

Only annoying problem is the engine will die quite often

at lights & the idle mixture is impossible to get

consistent.

26 / 12 / 00

It will be best to head

the updates with the date posted, this will make it

easier to follow. Below are two JPegs of scanned Dyno

results of my 15 / 12 / 00 date with Chiptorque. The man

himself, Lauchlan, conducted all the tuning runs & I

have to say I was most impressed with his thoughorness &

professionalism. Five problems that he predicted before,

reared there head during the session, although I also

knew three of them would happen, -run out of injectors,

-run out of air (air flow meter), -run out of fuel

(pump). I may be able to get away with the oe. pump, but

I'm upgrading it with the others to be safe, & also save

a possible third trip down the coast. The other two

things I overlooked were blow off valve venting to

atmosphere & tappet cover breather not connected to air

intake after air flow sensor. I vent the blow off valve

to atmosphere in my MX6 (rather my wife's now!) without

causing any problems & I hoped the Rodeo would be the

same, & I haven't received my air/oil separator,

intercooler recovery tank & Charcoal canister back from

HPC yet, so I didn't worry about connecting the hose.

Wrong on both counts, came home & plumbed both hoses

into intake & no more snuffing. It also muffled the blow

off noise, so I've gone from being a 17 year old hoon

back to a 50 year old petrolhead, god damn it !

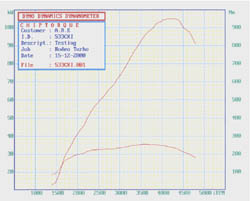

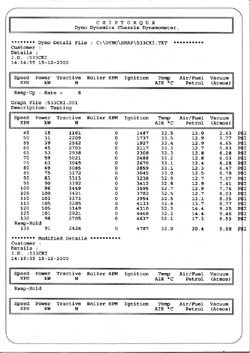

The above graph on the

left is the standard graph printed in most magazine

articles, with one exception, - the bottom scale is revs

& not kph. I want to know what it's got at a certain

rev., as it applies then in every gear, saving having to

work out rpm/rev later on. This is good & easy to look

at & compare with others, but I call it the "cosmetic"

graph. To me, the real "mechanics" graph is the chart

shown on the right side above. This gives the real

GUTS of the engine performance! It shows a much,

much more complete look at the engines capabilities &

potential, & off course, it's limitations & weaknesses.

Unfortunately, neither graph tells you the gear used for

the power runs, which is important to know. All tests on

my truck were conducted in fourth gear with

285/50 x 18" tyres.

Before I started, the

Rodeo had 62kw. @ 5850rpm at the wheels in third

gear on Brisbane Tuning & Turbo dyno (it will go back on

theirs when it's finished, for an accurate before/after

comparison), fitted with extractors & sports exhaust.

Chiptorque did a Rodeo with extractors, sports exhaust &

camshaft, with a resulting 67 kw., so I'm ecstatic with

my 105 kw.@ 4133 rpm, because we were starting to

run out of fuel, meaning there's more left in the old

girl yet, hopefully 140kw, which will be a 233% increase

in power. Even that is not the most impressive feature

of the engine, & unfortunately, I can't show you without

taking you for a ride! The boost is instantaneous - as I

squeeze the throttle, the boost needle rises straight

away, I kid you not. This is due to the expert (or

lucky) matching of the turbo (remember it's a new age

hybrid Garret) by John at Turbo Supplies, the extractor

exhaust & the extremely short inlet track of the

air/water intercooler (check it out compared to yours)!

I reckon the engine is hyperactive down low & Lauchlan

said it was like an angry ant on the rollers. To give

you some idea the above is true & I'm not exaggerating,

look at the boost figures & then compare to your known

figures, like 2.63 lb of boost at 1487rpm & 5.83lb of

boost at 2117 rpm, it's like driving a V8 automatic, no

bugger it, it's better than driving a V8 automatic!

I didn't even bother to

put ice in the "box" & am know wondering if I will be

able to test it's capabilities at all. The hottest turbo

outlet temp. was 72 deg. C, the hottest inlet temp

was 40.8 deg., the hottest water outlet temp (of

the 'cooler) was 38.4 deg. with a 'cooler inlet temp. of

36.7 deg., meaning the biggest "working" temperature

difference in the intercooler was 2.4 deg. when it was

removing 31.2 deg out of the inlet temp., however,

remember that this is only at 9.53lb boost. This was

also with the water pump on half speed. In the soft

sand, the water temp. started to climb above these

figures, but switching the pump to full 13V dropped the

temps. straight away. Of interest, I often see the

'cooler inlet temps. up to 3 deg. (but mostly 1.5 to 2

deg.) higher than the outlet temps, when I stop, due to

under bonnet heat soak. I have a couple of ideas to cut

down on this & will try to implement them before I go

back on the dyno.

Nothing under the tappet

cover has been touched yet, so the engine is completely

stock. When I fit larger injectors, air flow meter (off

a 200SX incidentally) & fuel pump, I will then get

Lauchlan to tune it for 10lb boost first, & then add

some avgas (I run Optimax now) & hopefully I can run 15

lb boost when I want to. It will be interesting to see

how long the engine lasts at these levels, but remember

three things, -1st -the engine is a commercial design -

meaning they are usually beefier than passenger car,

-2nd- it has 8.3:1 compression std., & with my normal

driving, it's usually 4' - 10'' vacuum, with occasional

4 -7 lb boost showing, which means most of the time the

engine is under no more stress than std. However, as

soon as I come across another engine, I will be buying

it & fitting forged pistons & rods, gapless rings & a

very mild turbo cam, as I know the current engine, isn't

going to last forever!

More Testing

6 weeks up to 17 / 02 / 01

a) This is the

SuperFlow 600E flow bench of Bryant Engineering (07-3846

2674) -(who incidentally have done all my engine

machining for 33 yrs)- is the biggest model available.

When testing intercoolers we have to have all eight

motors switched on & the fine adjustment set on either 5

of 6, or 6 of 6 & if I'm testing tanks only & even with

60mm pipes, I have to read the manometer at less

than the 25" normally used & then convert. That will

give you some idea of the air flow available through

intercoolers, necessitating the use of a powerful

machine for accurate results if doing allot of

experimentation. I am lucky & privileged to have the use

of this bench, but it may also result from building a

friendship & loyal customer over a long period.

b) I try to perfect

everything we sell. This is the best of 3 designs of the

intercooler water inlet tank. A parallel tube with13

holes drilled to supply a uniform pattern of water

equally to all the tubes running through the core. This

eliminates "hot & cold spots" I find in other products,

which is important to pull as much heat out of the

intake charge as is possible.

c) The 4 intercoolers to

be tested on the dyno, the tanks have yet to be welded

onto the 2 cores, right hand side. Note the 4

temperature probes used on the original 'cooler made for

the Rodeo. I'm positive the 92.8 % smaller size 'cooler

on the left of the original will prove to be noticeably

more effective at cooling the intake charge! This is

even though it has better air flow by 10.2%!!! This is

because of the totally different core construction we

use in this new line of intercoolers, suitable only in

air/water applications though! The smallest core (on the

right of the blue 'cooler) is 479% smaller than the blue

'cooler & flowed 2.3% better. The core on the far right

is 322.5% smaller & flowed 1.1% worse than the blue

'cooler. Note that the larger core on the right had

better flowing "radiused" tanks, so would've flowed less

again if fitted with the same tanks by a

calculated3.1%. Also note that air flow through the core

is only part of the heat dissipation equation, if core

construction is the same, usually the better flowing

core will actually cool the intake charge less.

d) The core

construction of these two intercoolers differs

completely & will give the unusual result of the

intercooler on the left with 10.2% better flow, cooling

the intake charge better than the larger, less flowing

blue 'cooler on the right &, originally fitted to the

Rodeo. Note that the colour has nothing to do with

cooling efficiency, as it is all internal in an

air/water setup & blue is constantly mentioned only to

distinguish the original intercooler fitted for the

first dyno session. The less restriction will also

result in more kilowatts, giving a double bonus!

Three Days Before "THE

FIRE"

I got the Rodeo back on

the road with a new fuel rail we fabricated for the high

flow injectors from Ray Box of Petro-Ject (07) - 3857

8022. They are Bosch part no.

to suit Mitsubishi TR Magnas& flowed 28% more fuel than

rodeo oe. units. Even though they had a different

impedance rating, they worked well enough to drive

around on until I could get onto Chiptorques dyno - rich

in the mid range. The truck just kept pulling hard right

up to 6K a couple of times that I tried it, wish I

had've been able to let Lauchlan do the final dyno

session.We also fitted a extra heavy duty clutch built

up by Dennis at Direct Clutches (07) 3862 2680. He had a

steel flywheel turned up to suit a Mazda RX7 upgraded

pressure plate & an organic Rodeo clutch plate. a

good job but it took 3 weeks longer than I was told.

really had allot of "bite", but was still progressive

enough to be able to do a hill start without the

handbrake.

Of course this now

means that the day booked on the dyno was cancelled

along with being able to size the four intercoolers I

had made. These will now be tested on the HiLux,

hopefully by June.

|

Atlas Engineering - 16L, 28 psi. Mulcher. |

|

ATLAS

ENGINEERING'S prototype forest mulcher.

Cummins 16 litre, 6 cyl., 450hp.,28 psi. |

|

This is

an11kb PDF file. Worth

a look

|

There is

a reason for the three pairs of tanks &

also for the different profiles of the

tanks. Yes !

This is

one of a few intercoolers that totally

overtaxed Bryant Engineerings flow

bench. In fact it is only limited by the

102mm inlet/outlet pipes. This is part

of the reason I don't list cfm figures,

some that I read are a complete

fabrication & would make ours look bad,

they are so easy to manipulate & are

unsubstantiated. Yeh, it pisses me off,

buts that's business.

The

explanations & text for this file are @

Research & Development

where you can see that under certain

conditions we got better than 100%

efficiency compared too both/either the

inlet water temp. & the ambient temp. It

shows that if I showed you a particular

second snapshot we have these figures,

but not under normal operation,

although we are still around 98% to the

water temp. & 73% to ambient - let down

by the radiator.

|

|

Check

back for updates.... Check

back for updates....

|

|